Page 418 - Iscar

P. 418

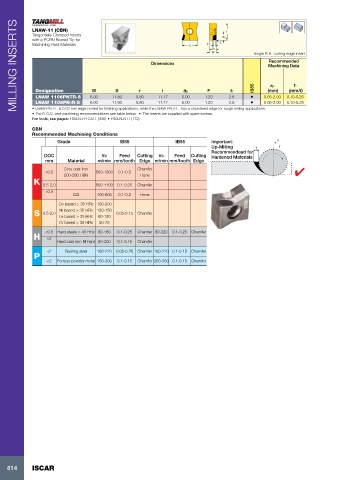

MILLING INSERTS LNAW-11 (CBN) Dimensions S F W lt r ap l IB85 Single R.H. cutting edge insert

Tangentially Clamped Inserts

with a PCBN Brazed Tip for

Machining Hard Materials

Recommended

Machining Data

ap

fz

F

Designation

S

r

l

(mm/t)

(mm)

W

lt

ap

1.20

LNAW 1106PNTR-S

0.80

11.80

5.00

6.00

11.17

•

0.05-2.00

5.00

6.00

11.17

0.80

11.90

1.20

LNAW 1106PN-R-S

2.8

0.10-0.25

• LNAW PN-R.. is 0.03 mm edge-honed for finishing applications, while the LNAW PNTR... has a chamfered edge for rough milling applications.

• For D.O.C. and machining recommendations see table below • The inserts are supplied with spare screws. 2.8 • 0.05-2.00 0.10-0.25

For tools, see pages: F90LN-FR CA11 (336) • F90LN-N11 (172)

CBN

Recommended Machining Conditions

Grade IB85 IB55 Important: v

Up-Milling f f

Recommendead for

DOC Vc Feed Cutting Vc Feed Cutting Hardened Materials

mm Material m/min mm/tooth Edge m/min mm/tooth Edge

Grey cast iron Chamfer

<0.5 500-1500 0.1-0.3

200-280 HBN Hone

K 0.5-2.0 500-1100 0.1-0.25 Chamfer

<0.5

CGI 400-600 0.1-0.2 Hone

Co based > 35 HRc 150-200

S 0.5-2.0 Ni based > 35 HRc 120-150 0.05-0.15 Chamfer

Fe based > 35 HRc

60-120

Cr based > 35 HRc 50-75

<0.5 Hard steels > 45 HRc 80-180 0.1-0.25 Chamfer 80-220 0.1-0.25 Chamfer

H <2

Hard cast iron Ni hard 80-200 0.1-0.15 Chamfer

<2 Bearing steel 180-220 0.05-0.25 Chamfer 180-220 0.1-0.15 Chamfer

P

<2 Ferrous powder metal 150-300 0.1-0.15 Chamfer 250-360 0.1-0.15 Chamfer

414 ISCAR