Page 416 - Iscar

P. 416

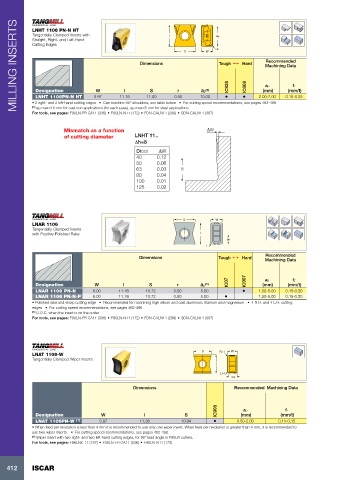

MILLING INSERTS LNHT 1106 PN-N HT Dimensions l S W ap r Tough 1 Hard Machining Data

Tangentially Clamped Inserts with

Straight, Right- and Left-Hand

Cutting Edges

Recommended

IC808

IC928

ap

fz

r

W

S

l

(mm)

(mm/t)

Designation

(1)

ap

10.00

LNHT 1106PN-N HT

5.97

11.00

11.16

0.80

• 2 right- and 2 left-hand cutting edges • Can machine 90° shoulders, see table below • For cutting speed recommendations, see pages 462-498

(1) ap max=10 mm for cast iron applications (for each pass), ap max=8 mm for steel applications

For tools, see pages: F90LN-FR CA11 (336) • F90LN-N11 (172) • FDN-CALN11 (299) • SDN-CALN11 (307) • • 2.00-7.00 0.15-0.25

Mismatch as a function ΔW

of cutting diameter LNHT 11..

Δh=8

Dtool ΔW

40 0.12

50 0.06

63 0.03 8

80 0.04

100 0.01

125 0.02

S W

LNAR 1106

Tangentially Clamped Inserts

with Positive Polished Rake l

ap

r

Recommended

Dimensions Tough 1 Hard

Machining Data

ap

fz

Designation W l S r ap (1) IC07 IC907 (mm) (mm/t)

LNAR 1106 PN-N 6.00 11.16 10.72 0.50 5.00 • 1.50-5.00 0.15-0.20

LNAR 1106 PN-N-P 6.00 11.16 10.72 0.50 5.00 • 1.50-5.00 0.15-0.20

• Polished rake and sharp cutting edge • Recommended for machining high silicon and cast aluminum, titanium and magnesium • 4 R.H. and 4 L.H. cutting

edges • For cutting speed recommendations, see pages 462-498

(1) D.O.C. when the insert is on the cutter

For tools, see pages: F90LN-FR CA11 (336) • F90LN-N11 (172) • FDN-CALN11 (299) • SDN-CALN11 (307)

LNAT 1106-W S R.H W

Tangentially Clamped Wiper Inserts

l

L.H

4.9

Dimensions Recommended Machining Data

IC908 ap fz

Designation W l S (mm) (mm/t)

LNAT 1106PN-W (1) 5.97 11.38 10.94 • 0.50-2.00 0.10-0.15

• When feed per revolution is less than 4 mm it is recommended to use only one wiper insert. When feed per revolution is greater than 4 mm, it is recommended to

use two wiper inserts. • For cutting speed recommendations, see pages 462-498

(1) Wiper insert with two right- and two left-hand cutting edges, for 90° lead angle in F90LN cutters.

For tools, see pages: F86LNX-11 (187) • F90LN-FR CA11 (336) • F90LN-N11 (172)

412 ISCAR