Page 417 - Iscar

P. 417

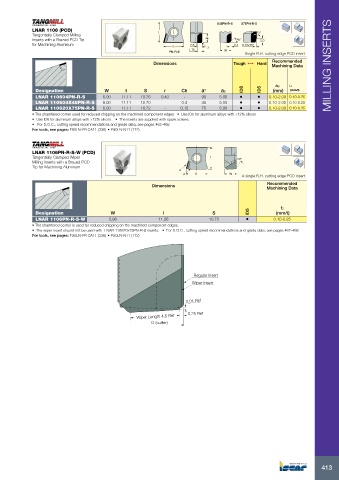

X45PN-R-S X75PN-R-S

LNAR 1106 (PCD) I 15°

Tangentially Clamped Milling

Inserts with a Brazed PCD Tip ap 45° 2.0

for Machining Aluminum 2.6 0.4 0.15x75°

S r

1.75 W

PN-R-S Single R.H. cutting edge PCD insert

Recommended

Dimensions Tough 1 Hard

Machining Data MILLING INSERTS

ap fz

Designation W l S r Ch a° ap ID8 ID5 (mm) (mm/t)

LNAR 110604PN-R-S 6.00 11.11 10.76 0.40 - 90 5.00 • • 0.10-2.00 0.10-0.25

LNAR 110604X45PN-R-S 6.00 11.11 10.70 - 0.4 45 5.00 • • 0.10-2.00 0.10-0.25

LNAR 110620X75PN-R-S 6.00 11.11 10.72 - 0.15 75 5.00 • • 0.10-2.00 0.10-0.25

• The chamfered corner used for reduced chipping on the machined component edges • Use ID5 for aluminum alloys with <12% silicon

• Use ID8 for aluminum alloys with >12% silicon. • The inserts are supplied with spare screws.

• For D.O.C., cutting speed recommendations and grade data, see pages 462-468

For tools, see pages: F90LN-FR CA11 (336) • F90LN-N11 (172)

LNAR 1106PN-R-S-W (PCD)

Tangentially Clamped Wiper l 30º

Milling Inserts with a Brazed PCD

Tip for Machining Aluminum

A

A S W

A single R.H. cutting edge PCD insert

Recommended

Dimensions

Machining Data

fz

Designation W l S ID5 (mm/t)

LNAR 1106PN-R-S-W 5.98 11.26 10.75 • 0.10-0.25

• The chamfered corner is used for reduced chipping on the machined component edges.

• The wiper insert should not be used with LNAR 110620x75PN-R-S inserts. • For D.O.C., cutting speed recommendations and grade data, see pages 462-468

For tools, see pages: F90LN-FR CA11 (336) • F90LN-N11 (172)

Regular Insert

Wiper Insert

0.01 Ref

0.25 Ref

Wiper Length 4.6 Ref

D (cutter)

413