Page 413 - Iscar

P. 413

1 2 Rd°

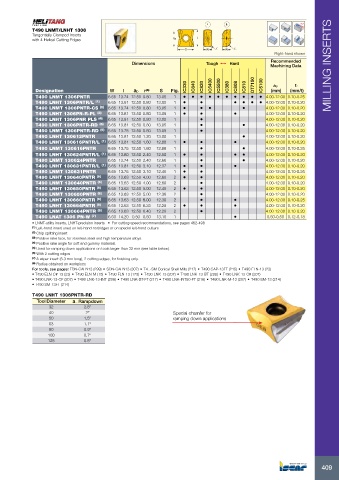

T490 LNMT/LNHT 1306

Tangentially Clamped Inserts l

with 4 Helical Cutting Edges ap

S W r W r

Right-hand shown

Recommended

Dimensions Tough 1 Hard

Machining Data MILLING INSERTS

IC330 IC840 IC830 IC5400 IC5500 IC380 IC808 IC810 DT7150 IC5100 ap fz

Designation W l ap r (8) S Fig. (mm) (mm/t)

T490 LNMT 1306PNTR 6.65 13.74 12.50 0.80 13.05 1 • • • • • • • • • • 4.00-12.00 0.10-0.25

T490 LNHT 1306PNTR/L (1) 6.65 13.81 12.50 0.80 13.05 1 • • • • • • 4.00-12.00 0.10-0.20

T490 LNMT 1306PNTR-CS (2) 6.65 13.74 12.50 0.80 13.05 1 • • • • 4.00-12.00 0.10-0.20

T490 LNHT 1306PN-R-PL (3) 6.65 13.81 12.50 0.80 13.05 1 • • • 4.00-12.00 0.10-0.20

T490 LNHT 1306PNR PLS (4) 6.65 13.81 12.50 0.80 13.05 1 • 4.00-12.00 0.10-0.20

T490 LNHT 1306PNTR-RD (5) 6.65 13.81 12.50 0.80 13.05 1 • • 4.00-12.00 0.10-0.20

T490 LNMT 1306PNTR-RD (5) 6.65 13.75 12.50 0.80 13.05 1 • 4.00-12.00 0.10-0.20

T490 LNHT 130612PNTR 6.65 13.81 12.50 1.20 13.00 1 • 4.00-12.00 0.10-0.20

T490 LNHT 130616PNTR/L (1) 6.65 13.81 12.50 1.60 12.88 1 • • • 4.00-12.00 0.10-0.20

T490 LNMT 130616PNTR 6.65 13.75 12.50 1.60 12.88 1 • • 4.00-12.00 0.10-0.25

T490 LNHT 130624PNTR/L (1) 6.65 13.80 12.50 2.40 12.50 1 • • • • 4.00-12.00 0.10-0.20

T490 LNMT 130624PNTR 6.65 13.74 12.50 2.40 12.66 1 • • 4.00-12.00 0.10-0.20

T490 LNHT 130631PNTR/L (1) 6.65 13.81 12.50 3.10 12.37 1 • • • 4.00-12.00 0.10-0.20

T490 LNMT 130631PNTR 6.65 13.75 12.50 3.10 12.45 1 • • 4.00-12.00 0.10-0.25

T490 LNHT 130640PNTR (6) 6.65 13.63 12.50 4.00 12.60 2 • • 4.00-12.00 0.10-0.20

T490 LNMT 130640PNTR (6) 6.65 13.63 12.50 4.00 12.60 2 • 4.00-12.00 0.10-0.20

T490 LNHT 130650PNTR (6) 6.65 13.63 12.50 5.00 12.45 2 • • 4.00-12.00 0.10-0.20

T490 LNMT 130650PNTR (6) 6.65 13.63 12.50 5.00 12.36 2 • 4.00-12.00 0.10-0.20

T490 LNHT 130660PNTR (6) 6.65 13.63 12.50 6.00 12.30 2 • • 4.00-12.00 0.10-0.25

T490 LNHT 130664PNTR (6) 6.65 13.63 12.50 6.35 12.28 2 • • • 4.00-12.00 0.10-0.20

T490 LNMT 130664PNTR (6) 6.65 13.63 12.50 6.40 12.28 2 • 4.00-12.00 0.10-0.20

T490 LNAT 1306 PN-W (7) 6.60 14.20 0.50 0.50 13.10 1 • 0.50-0.50 0.12-0.18

• LNMT-utility inserts, LNHT-precision inserts • For cutting speed recommendations, see pages 462-498

(1) Left-hand insert used on left-hand cartridges or on special left-hand cutters

(2) Chip splitting insert

(3) Positive rake face, for stainless steel and high temperature alloys.

(4) Positive rake angle for soft and gummy materials

(5) Used for ramping down applications on tools larger than 32 mm (see table below).

(6) With 2 cutting edges

(7) A wiper insert (5.3 mm long), 2 cutting edges, for finishing only.

(8) Radius obtained on workpiece

For tools, see pages: FDN-CALN13 (299) • SDN-CALN13 (307) • T4..-SM Conical Shell Mills (217) • T490 CAP-13FT (215) • T490 ELN-13 (23)

• T490 ELN-C#-13 (23) • T490 ELN-M (15) • T490 FLN-13 (175) • T490 LNK-13 (207) • T490 LNK-13-BT (208) • T490 LNK-13-C# (207)

• T490 LNK-13-CF (207) • T490 LNK-13-INT (208) • T490 LNK-BT-FT (217) • T490 LNK-INT50-FT (216) • T490 LNK-M-13 (207) • T490 SM-13 (214)

• T490 SM-13FT (214)

T490 LNHT 1306PNTR-RD

Tool Diameter a - Rampdown

32 2.8°

40 2° Special chamfer for

50 1.5° ramping down applications

63 1.1°

80 0.9°

100 0.7°

125 0.5°

409