Page 572 - Dormer

P. 572

GENERAL HINTS

THREADING

GENERAL HINTS ON TAPPING

The success of any tapping operation depends on a number of factors, all of which affect the quality of the finished

product.

1. Select the correct design of tap for the component material and type of hole, i.e. through or blind, from the Materials

Classification chart.

2. Ensure the component is securely clamped - lateral movement may cause tap breakage or poor quality threads.

3. Select the correct size of drill from the relevant catalogue page. Always ensure that work hardening of the component

material is kept to a minimum.

4. Select the correct cutting speed as shown on the catalogue product page.

5. Use appropriate cutting fluid for correct application.

6. In NC applications ensure that the feed value chosen for the program is correct. When using a tapping attachment,

95% to 97% of the pitch is recommended to allow the tap to generate its own pitch.

7. Where possible, hold the tap in a good quality torque limiting tapping attachment, which ensures free axial move-

ment of the tap and presents it squarely to the hole. It also protects the tap from breakage if accidentally ‘bottomed’

in a blind hole.

8. Ensure smooth entry of the tap into the hole, as an uneven feed may cause ‘bell mouthing’.

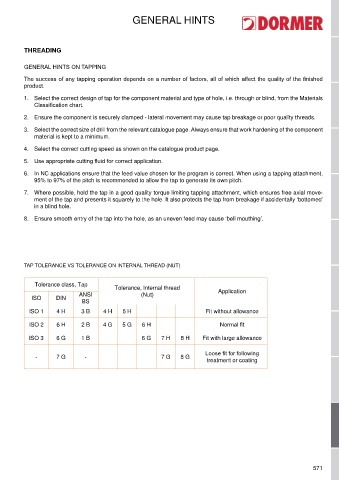

TAP TOLERANCE VS TOLERANCE ON INTERNAL THREAd (NUT)

Tolerance class, Tap

Tolerance, Internal thread

ANSI (Nut) Application

ISO DIN

BS

ISO 1 4 H 3 B 4 H 5 H Fit without allowance

ISO 2 6 H 2 B 4 G 5 G 6 H Normal fit

ISO 3 6 G 1 B 6 G 7 H 8 H Fit with large allowance

Loose fit for following

- 7 G - 7 G 8 G

treatment or coating

571