Page 570 - Dormer

P. 570

GENERAL HINTS

THREAD MILLING

GENERAL HINTS ON THREAd MILLING

1. Thread milling is the process of generating a thread by the circular interpolation of a milling cutter with a specific

thread geometry ground around it’s periphery.

2. To be able to use a thread milling cutter it is necessary to have a CNC machine that can make circular paths.

3. Most modern CNC machines are equipped with machining cycles for thread milling

4. Consult the manual or contact the machine supplier for information

FEATURES ANd BENEFITS

1. Thread milling gives increased reliability and tool life

2. Threadmills produce small chips resulting in problem free threading

3. Tolerance adjustments can be made using exact co-ordinates

4. You can generate a fuller thread to the bottom of the hole

5. Capable of machining a wide variety of materials

6. The same cutter can produce different size threads provided the pitch is the same

7. Both right and left hand threads can be created with the same tool

8. Some thread mills can also machine the entry chamfer (J200, J205, J260)

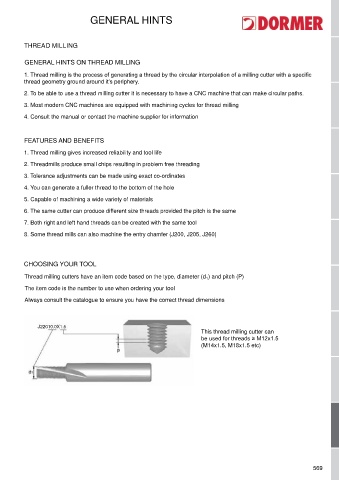

CHOOSING YOUR TOOL

Thread milling cutters have an item code based on the type, diameter (d ) and pitch (P)

1

The item code is the number to use when ordering your tool

Always consult the catalogue to ensure you have the correct thread dimensions

J22010.0X1.5

This thread milling cutter can

be used for threads ≥ M12x1.5

(M14x1.5, M18x1.5 etc)

569