Page 566 - Dormer

P. 566

GENERAL HINTS

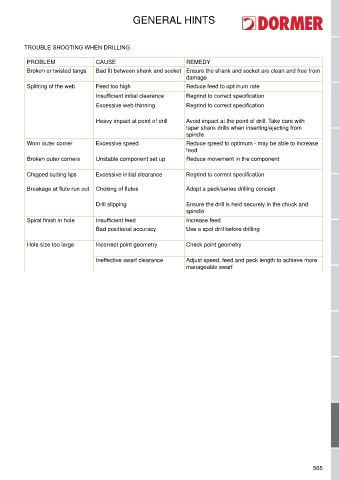

TROUBLE SHOOTING WHEN DRILLING

PROBLEM CAUSE REMEDY

Broken or twisted tangs Bad fit between shank and socket Ensure the shank and socket are clean and free from

damage

Splitting of the web Feed too high Reduce feed to optimum rate

Insufficient initial clearance Regrind to correct specification

Excessive web thinning Regrind to correct specification

Heavy impact at point of drill Avoid impact at the point of drill. Take care with

taper shank drills when inserting/ejecting from

spindle

Worn outer corner Excessive speed Reduce speed to optimum - may be able to increase

feed

Broken outer corners Unstable component set up Reduce movement in the component

Chipped cutting lips Excessive initial clearance Regrind to correct specification

Breakage at flute run out Choking of flutes Adopt a peck/series drilling concept

drill slipping Ensure the drill is held securely in the chuck and

spindle

Spiral finish in hole Insufficient feed Increase feed

Bad positional accuracy Use a spot drill before drilling

Hole size too large Incorrect point geometry Check point geometry

Ineffective swarf clearance Adjust speed, feed and peck length to achieve more

manageable swarf

565