Page 569 - Dormer

P. 569

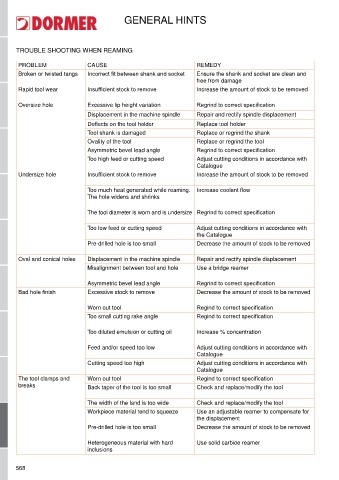

GENERAL HINTS

TROUBLE SHOOTING WHEN REAMING

PROBLEM CAUSE REMEDY

Broken or twisted tangs Incorrect fit between shank and socket Ensure the shank and socket are clean and

free from damage

Rapid tool wear Insufficient stock to remove Increase the amount of stock to be removed

Oversize hole Excessive lip height variation Regrind to correct specification

displacement in the machine spindle Repair and rectify spindle displacement

Deflects on the tool holder Replace tool holder

Tool shank is damaged Replace or regrind the shank

Ovality of the tool Replace or regrind the tool

Asymmetric bevel lead angle Regrind to correct specification

Too high feed or cutting speed Adjust cutting conditions in accordance with

Catalogue

Undersize hole Insufficient stock to remove Increase the amount of stock to be removed

Too much heat generated while reaming. Increase coolant flow

The hole widens and shrinks

The tool diameter is worn and is undersize Regrind to correct specification

Too low feed or cutting speed Adjust cutting conditions in accordance with

the Catalogue

Pre-drilled hole is too small decrease the amount of stock to be removed

Oval and conical holes displacement in the machine spindle Repair and rectify spindle displacement

Misalignment between tool and hole Use a bridge reamer

Asymmetric bevel lead angle Regrind to correct specification

Bad hole finish Excessive stock to remove decrease the amount of stock to be removed

Worn out tool Regind to correct specification

Too small cutting rake angle Regind to correct specification

Too diluted emulsion or cutting oil Increase % concentration

Feed and/or speed too low Adjust cutting conditions in accordance with

Catalogue

Cutting speed too high Adjust cutting conditions in accordance with

Catalogue

The tool clamps and Worn out tool Regind to correct specification

breaks Back taper of the tool is too small Check and replace/modify the tool

The width of the land is too wide Check and replace/modify the tool

Workpiece material tend to squeeze Use an adjustable reamer to compensate for

the displacement

Pre-drilled hole is too small decrease the amount of stock to be removed

Heterogeneous material with hard Use solid carbide reamer

inclusions

568