Page 574 - Dormer

P. 574

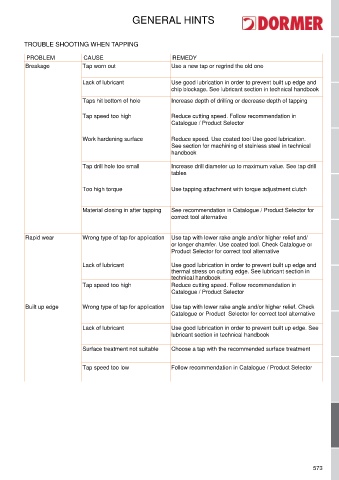

GENERAL HINTS

TROUBLE SHOOTING WHEN TAPPING

PROBLEM CAUSE REMEDY

Breakage Tap worn out Use a new tap or regrind the old one

Lack of lubricant Use good lubrication in order to prevent built up edge and

chip blockage. See lubricant section in technical handbook

Taps hit bottom of hole Increase depth of drilling or decrease depth of tapping

Tap speed too high Reduce cutting speed. Follow recommendation in

Catalogue / Product Selector

Work hardening surface Reduce speed. Use coated tool Use good lubrication.

See section for machining of stainless steel in technical

handbook

Tap drill hole too small Increase drill diameter up to maximum value. See tap drill

tables

Too high torque Use tapping attachment with torque adjustment clutch

Material closing in after tapping See recommendation in Catalogue / Product Selector for

correct tool alternative

Rapid wear Wrong type of tap for application Use tap with lower rake angle and/or higher relief and/

or longer chamfer. Use coated tool. Check Catalogue or

Product Selector for correct tool alternative

Lack of lubricant Use good lubrication in order to prevent built up edge and

thermal stress on cutting edge. See lubricant section in

technical handbook

Tap speed too high Reduce cutting speed. Follow recommendation in

Catalogue / Product Selector

Built up edge Wrong type of tap for application Use tap with lower rake angle and/or higher relief. Check

Catalogue or Product Selector for correct tool alternative

Lack of lubricant Use good lubrication in order to prevent built up edge. See

lubricant section in technical handbook

Surface treatment not suitable Choose a tap with the recommended surface treatment

Tap speed too low Follow recommendation in Catalogue / Product Selector

573