Page 577 - Dormer

P. 577

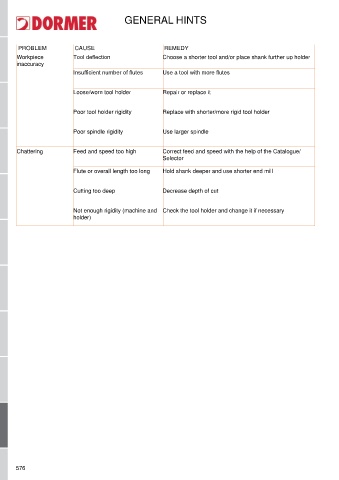

GENERAL HINTS

PROBLEM CAUSE REMEDY

Workpiece Tool deflection Choose a shorter tool and/or place shank further up holder

inaccuracy

Insufficient number of flutes Use a tool with more flutes

Loose/worn tool holder Repair or replace it

Poor tool holder rigidity Replace with shorter/more rigid tool holder

Poor spindle rigidity Use larger spindle

Chattering Feed and speed too high Correct feed and speed with the help of the Catalogue/

Selector

Flute or overall length too long Hold shank deeper and use shorter end mill

Cutting too deep Decrease depth of cut

Not enough rigidity (machine and Check the tool holder and change it if necessary

holder)

576