Page 576 - Dormer

P. 576

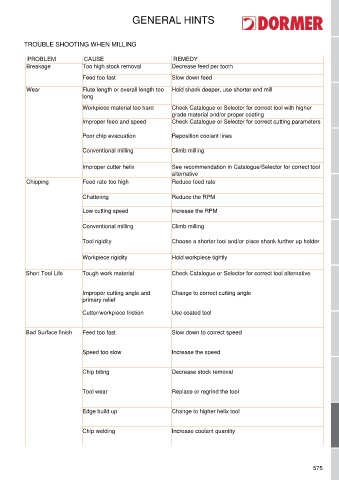

GENERAL HINTS

TROUBLE SHOOTING WHEN MILLING

PROBLEM CAUSE REMEDY

Breakage Too high stock removal Decrease feed per tooth

Feed too fast Slow down feed

Wear Flute length or overall length too Hold shank deeper, use shorter end mill

long

Workpiece material too hard Check Catalogue or Selector for correct tool with higher

grade material and/or proper coating

Improper feed and speed Check Catalogue or Selector for correct cutting parameters

Poor chip evacuation Reposition coolant lines

Conventional milling Climb milling

Improper cutter helix See recommendation in Catalogue/Selector for correct tool

alternative

Chipping Feed rate too high Reduce feed rate

Chattering Reduce the RPM

Low cutting speed Increase the RPM

Conventional milling Climb milling

Tool rigidity Choose a shorter tool and/or place shank further up holder

Workpiece rigidity Hold workpiece tightly

Short Tool Life Tough work material Check Catalogue or Selector for correct tool alternative

Improper cutting angle and Change to correct cutting angle

primary relief

Cutter/workpiece friction Use coated tool

Bad Surface finish Feed too fast Slow down to correct speed

Speed too slow Increase the speed

Chip biting Decrease stock removal

Tool wear Replace or regrind the tool

Edge build up Change to higher helix tool

Chip welding Increase coolant quantity

575