Page 567 - Dormer

P. 567

GENERAL HINTS

REAMING

GENERAL HINTS ON REAMING

To obtain the best results when using reamers it is essential to make them ‘work’. It is a common fault to prepare holes

for reaming with too little stock left in. If insufficient stock is left in the hole before reaming, then the reamer will rub,

quickly show wear and will result in loss of diameter. It is equally important for performance not to leave too much stock

in the hole. (See Stock Removal below).

1. Select the optimum type of reamer and the optimum speeds and feeds for the application. Ensure that pre-drilled

holes are the correct diameter.

2. The workpiece must be held rigid and the machine spindle should have no play.

3. The chuck in which a straight shank reamer is held must be good quality. If the reamer slips in the chuck and the

feed is automatic, breakage of the reamer may occur.

4. Keep tool overhang from machine spindle to a minimum.

5. Use recommended lubricants to enhance the life of the reamer and ensure the fluid reaches the cutting edges. As

reaming is not a heavy cutting operation, soluble oil 40:1 dilution is normally satisfactory. Air blasting may be used

with grey cast iron, if dry machining.

6. Do not allow the flutes of a reamer to become blocked with swarf.

7. Before the reamer is reground, check concentricity between centres. In most instances only the bevel lead will need

regrinding.

8. Keep reamers sharp. Frequent regrinding is good economy, but it is important to understand that reamers cut only

on the bevel and taper leads and not on the lands. Consequently only these leads need regrinding. Accuracy of

regrinding is important to hole quality and tool life.

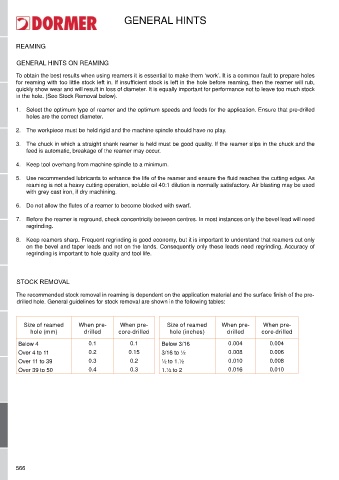

STOCK REMOVAL

The recommended stock removal in reaming is dependent on the application material and the surface finish of the pre-

drilled hole. General guidelines for stock removal are shown in the following tables:

Size of reamed When pre- When pre- Size of reamed When pre- When pre-

hole (mm) drilled core-drilled hole (inches) drilled core-drilled

Below 4 0.1 0.1 Below 3/16 0.004 0.004

Over 4 to 11 0.2 0.15 3/16 to ½ 0.008 0.006

Over 11 to 39 0.3 0.2 ½ to 1.½ 0.010 0.008

Over 39 to 50 0.4 0.3 1.½ to 2 0.016 0.010

566