Page 586 - Iscar

P. 586

USER GUIDE

SOLID CARBIDE DRILLS

3 Flute Solid Carbide Drills

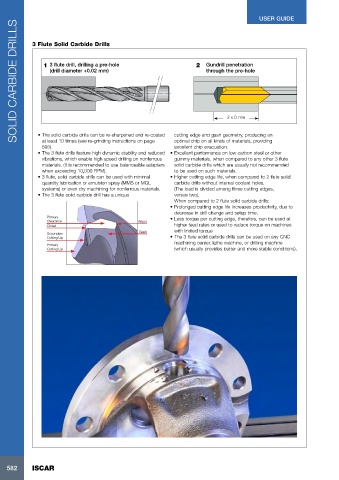

1 3 flute drill, drilling a pre-hole 2 Gundrill penetration

(drill diameter +0.02 mm) through the pre-hole

2 x D min

• The solid carbide drills can be re-sharpened and re-coated cutting edge and gash geometry, producing an

at least 10 times (see re-grinding instructions on page optimal chip on all kinds of materials, providing

595). excellent chip evacuation.

• The 3 flute drills feature high dynamic stability and reduced • Excellent performance on low carbon steel or other

vibrations, which enable high speed drilling on nonferrous gummy materials, when compared to any other 3 flute

materials. (It is recommended to use balanceable adapters solid carbide drills which are usually not recommended

when exceeding 10,000 RPM). to be used on such materials.

• 3 flute, solid carbide drills can be used with minimal • Higher cutting edge life, when compared to 2 flute solid

quantity lubrication or emulsion spray (MMS or MQL carbide drills without internal coolant holes.

systems) or even dry machining for nonferrous materials. (The load is divided among three cutting edges,

• The 3 flute solid carbide drill has a unique versus two).

When compared to 2 flute solid carbide drills:

• Prolonged cutting edge life increases productivity, due to

decrease in drill change and setup time.

Primary • Less torque per cutting edge, therefore, can be used at

Clearance Wiper

Chisel higher feed rates or used to reduce torque on machines

Secondary Gash with limited torque

Cutting Lip • The 3 flute solid carbide drills can be used on any CNC

machining center, lathe machine, or drilling machine

Primary

Cutting Lip (which usually provides better and more stable conditions).

ISCAR

582 ISCAR

582