Page 589 - Iscar

P. 589

USER GUIDE

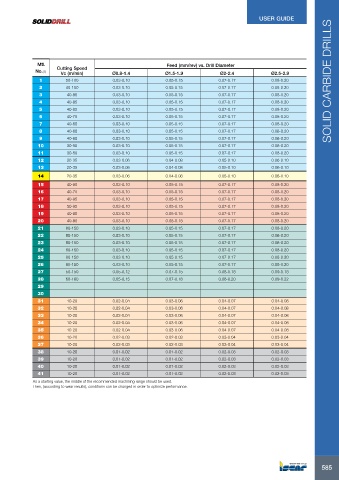

Mtl. Feed (mm/rev) vs. Drill Diameter

Cutting Speed

No.(1)

Vc (m/min) Ø0.8-1.4 Ø1.5-1.9 Ø2-2.4 Ø2.5-2.9

1 50-100 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20 SOLID CARBIDE DRILLS

2 40-100 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

3 40-85 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

4 40-85 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

5 40-85 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

6 40-75 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

7 40-60 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

8 40-60 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

9 40-60 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

10 30-50 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

11 30-50 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

12 20-35 0.03-0.06 0.04-0.08 0.05-0.10 0.06-0.10

13 20-35 0.03-0.06 0.04-0.08 0.05-0.10 0.06-0.10

14 20-35 0.03-0.06 0.04-0.08 0.05-0.10 0.06-0.10

15 40-80 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

16 40-70 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

17 40-95 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

18 50-95 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

19 40-80 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

20 40-80 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

21 80-150 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

22 80-150 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

23 80-150 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

24 80-150 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

25 80-150 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

26 80-150 0.03-0.10 0.05-0.15 0.07-0.17 0.08-0.20

27 50-150 0.05-0.12 0.07-0.15 0.08-0.18 0.09-0.18

28 60-160 0.05-0.15 0.07-0.18 0.08-0.20 0.09-0.22

29

30

31 10-20 0.02-0.04 0.03-0.06 0.04-0.07 0.04-0.08

32 10-20 0.02-0.04 0.03-0.06 0.04-0.07 0.04-0.08

33 10-20 0.02-0.04 0.03-0.06 0.04-0.07 0.04-0.08

34 10-20 0.02-0.04 0.03-0.06 0.04-0.07 0.04-0.08

35 10-20 0.02-0.04 0.03-0.06 0.04-0.07 0.04-0.08

36 10-20 0.02-0.03 0.02-0.03 0.03-0.04 0.03-0.04

37 10-20 0.02-0.03 0.02-0.03 0.03-0.04 0.03-0.04

38 10-20 0.01-0.02 0.01-0.02 0.02-0.03 0.02-0.03

39 10-20 0.01-0.02 0.01-0.02 0.02-0.03 0.02-0.03

40 10-20 0.01-0.02 0.01-0.02 0.02-0.03 0.02-0.03

41 10-20 0.01-0.02 0.01-0.02 0.02-0.03 0.02-0.03

As a starting value, the middle of the recommended machining range should be used.

Then, (according to wear results), conditions can be changed in order to optimize performance.

585

585