Page 401 - Iscar

P. 401

W

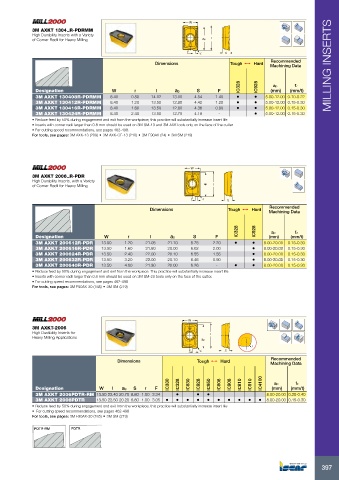

3M AXKT 1304..R-PDRMM

High Durability Inserts with a Variety

of Corner Radii for Heavy Milling ap l

F r S

Recommended

Dimensions Tough 1 Hard

Machining Data MILLING INSERTS

IC328 IC928 ap fz

Designation W r l ap S F (mm) (mm/t)

3M AXKT 130408R-PDRMM 8.40 0.80 14.12 13.00 4.54 1.40 • • 5.00-12.00 0.10-0.22

3M AXKT 130412R-PDRMM 8.40 1.20 13.50 12.80 4.42 1.20 • • 5.00-12.00 0.15-0.30

3M AXKT 130416R-PDRMM 8.40 1.60 13.50 12.80 4.36 0.80 • • 5.00-12.00 0.15-0.30

3M AXKT 130424R-PDRMM 8.40 2.40 13.50 12.75 4.18 - • 5.00-12.00 0.15-0.30

• Reduce feed by 50% during engagement and exit from the workpiece; this practice will substantially increase insert life

• Inserts with corner radii larger than 0.8 mm should be used on 3M SM-13 and 3M AXK tools only on the face of the cutter

• For cutting speed recommendations, see pages 462-498.

For tools, see pages: 3M AXK-13 (209) • 3M AXK-CF-13 (210) • 3M E90AX (24) • 3M SM (219)

W

3M AXKT 2006..R-PDR

High Durability Inserts, with a Variety

of Corner Radii for Heavy Milling ap l

F r S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC928 ap fz

Designation W r l ap S F (mm) (mm/t)

3M AXKT 200612R-PDR 13.50 1.20 21.05 21.10 6.75 2.20 • • 8.00-20.00 0.15-0.30

3M AXKT 200616R-PDR 13.50 1.60 21.80 20.00 6.62 2.00 • 8.00-20.00 0.15-0.30

3M AXKT 200624R-PDR 13.50 2.40 22.00 20.10 6.55 1.55 • 8.00-20.00 0.15-0.30

3M AXKT 200632R-PDR 13.50 3.20 22.00 20.10 6.46 0.90 • 8.00-20.00 0.15-0.30

3M AXKT 200640R-PDR 13.50 4.00 21.90 20.00 6.26 - • • 8.00-20.00 0.15-0.30

• Reduce feed by 50% during engagement and exit from the workpiece. This practice will substantially increase insert life.

• Inserts with corner radii larger than 0.8 mm should be used on 3M SM-20 tools only on the face of the cutter.

• For cutting speed recommendations, see pages 462-498

For tools, see pages: 3M F90AX-20 (185) • 3M SM (219)

W

3M AXKT-2006

High Durability Inserts for l

Heavy Milling Applications

ap

r

F r S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC330 IC328 IC830 IC928 IC950 IC808 IC908 IC810 IC910 IC4100 ap fz

Designation W l ap S r F (mm) (mm/t)

3M AXKT 2006PDTR-RM 13.50 22.40 20.70 6.80 1.00 3.34 • • • 8.00-20.00 0.20-0.40

3M AXKT 2006PDTR 13.50 22.50 20.20 6.80 1.00 3.05 • • • • • • • • • • 8.00-20.00 0.15-0.30

• Reduce feed by 50% during engagement and exit from the workpiece; this practice will substantially increase insert life

• For cutting speed recommendations, see pages 462-498

For tools, see pages: 3M F90AX-20 (185) • 3M SM (219)

PDTR-RM PDTR

397