Page 405 - Iscar

P. 405

W Rd°

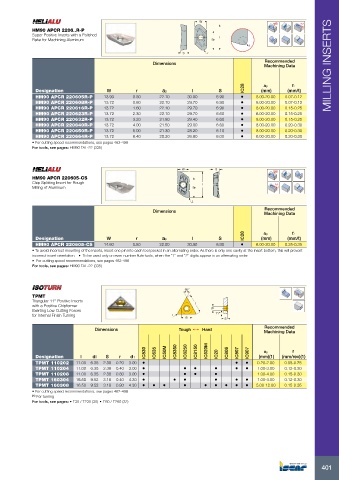

HM90 APCR 2206..R-P

Super Positive Inserts with a Polished l

Rake for Machining Aluminum ap

r

S r

Recommended

Dimensions

Machining Data MILLING INSERTS

fz

ap

Designation W r ap l S IC28 (mm) (mm/t)

HM90 APCR 220605R-P 13.90 0.50 22.10 30.50 6.90 • 8.00-20.00 0.07-0.12

HM90 APCR 220608R-P 13.72 0.80 22.10 29.70 6.90 • 8.00-20.00 0.07-0.12

HM90 APCR 220616R-P 13.72 1.60 22.10 29.70 6.90 • 8.00-20.00 0.15-0.25

HM90 APCR 220623R-P 13.72 2.30 22.10 29.70 6.60 • 8.00-20.00 0.15-0.25

HM90 APCR 220632R-P 13.72 3.20 21.80 29.40 6.60 • 8.00-20.00 0.15-0.25

HM90 APCR 220640R-P 13.72 4.00 21.50 29.00 6.60 • 8.00-20.00 0.20-0.30

HM90 APCR 220650R-P 13.72 5.00 21.30 28.20 6.10 • 8.00-20.00 0.20-0.30

HM90 APCR 220664R-P 13.72 6.40 20.30 26.80 6.00 • 8.00-20.00 0.20-0.30

• For cutting speed recommendations, see pages 462-498

For tools, see pages: HM90 FAL-22 (335)

W S

HM90 APCR 220605-CS

Chip Splitting Insert for Rough l Rd°

Milling of Aluminum ap

r

Recommended

Dimensions

Machining Data

ap

fz

Designation W r ap l S IC28 (mm) (mm/t)

HM90 APCR 220605-CS 14.60 0.50 22.00 30.90 6.90 • 8.00-20.00 0.25-0.35

• To avoid incorrect mounting of the inserts, insert one pin into each tool pocket in an alternating order. As there is only one cavity at the insert bottom, this will prevent

incorrect insert orientation. • To be used only on even number flute tools, when the "1" and "2" digits appear in an alternating order.

• For cutting speed recommendations, see pages 462-498

For tools, see pages: HM90 FAL-22 (335)

60°

TPMT

Triangular 11° Positive Inserts l

with a Positive Chipformer d1

Exerting Low Cutting Forces 11°

for Internal Finish Turning r

di S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC635 IC50M IC8350 IC8250 IC8150 IC520M IC806 IC807 IC907 ap f

Designation l di S r d1 IC20 (mm)(1) (mm/rev)(1)

TPMT 110202 11.00 6.35 2.38 0.20 3.00 • • • 0.20-2.00 0.05-0.25

TPMT 110204 11.00 6.35 2.38 0.40 3.00 • • • • • • 1.00-3.00 0.12-0.30

TPMT 110208 11.00 6.35 2.38 0.80 3.00 • • • • 1.00-4.00 0.15-0.30

TPMT 160304 16.50 9.52 3.18 0.40 4.30 • • • • • • 1.00-4.00 0.12-0.30

TPMT 160308 16.50 9.52 3.18 0.80 4.30 • • • • • • • • • 5.00-12.00 0.15-0.35

• For cutting speed recommendations, see pages 462-498

(1) For turning

For tools, see pages: • E30 / T230 (30) • E60 / T260 (32)

401