Page 395 - Iscar

P. 395

W

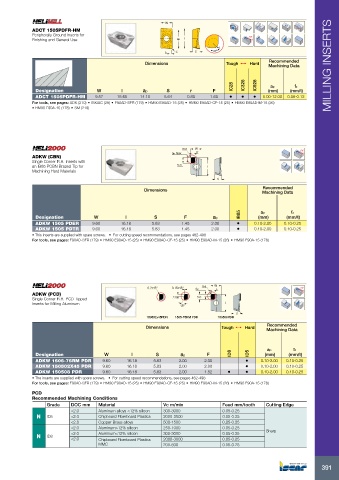

ADCT 1505PDFR-HM

Peripherally Ground Inserts for Rd°

Finishing and General Use ap l

r

F r S 25°

Recommended

Dimensions Tough 1 Hard

Machining Data MILLING INSERTS

IC28 IC328 IC928 ap fz

Designation W l ap S r F (mm) (mm/t)

ADCT 1505PDFR-HM 9.57 15.65 14.10 5.64 0.80 1.60 • • • 5.00-12.00 0.06-0.12

For tools, see pages: ADK (210) • E90AC (29) • F90AD-SFR (179) • HM90 E90AD-15 (25) • HM90 E90AD-CF-15 (25) • HM90 E90AD-M-15 (26)

• HM90 F90A-15 (178) • SM (219)

ap max r0.8 W F Rd°

ADKW (CBN)

Single Corner R.H. Inserts with

an IB85 PCBN Brazed Tip for 5.0 I

Machining Hard Materials

S

Recommended

Dimensions

Machining Data

fz

ap

Designation W l S F ap IB85 (mm) (mm/t)

ADKW 1505 PDER 9.60 16.18 5.83 1.45 2.00 • 0.10-2.00 0.10-0.25

ADKW 1505 PDTR 9.60 16.18 5.83 1.45 2.00 • 0.10-2.00 0.10-0.25

• This inserts are supplied with spare screws. • For cutting speed recommendations, see pages 462-498

For tools, see pages: F90AD-SFR (179) • HM90 E90AD-15 (25) • HM90 E90AD-CF-15 (25) • HM90 E90AD-M-15 (26) • HM90 F90A-15 (178)

0.2x45° 0.15x45° ap r0.8 W F Rd°

ADKW (PCD)

Single Corner R.H. PCD Tipped 2.0 5.0

Inserts for Milling Aluminum I

15º

S

150502x45PDR 1505-75RM PDR 150508PDR

Recommended

Dimensions Tough 1 Hard Machining Data

ap fz

Designation W l S ap F ID8 ID5 (mm) (mm/t)

ADKW 1505-75RM PDR 9.60 16.18 5.83 2.00 2.00 • 0.10-2.00 0.10-0.25

ADKW 150502X45 PDR 9.60 16.18 5.83 2.00 2.00 • 0.10-2.00 0.10-0.25

ADKW 150508 PDR 9.60 16.18 5.83 2.00 1.52 • • 0.10-2.00 0.10-0.25

• The inserts are supplied with spare screws. • For cutting speed recommendations, see pages 462-498

For tools, see pages: F90AD-SFR (179) • HM90 E90AD-15 (25) • HM90 E90AD-CF-15 (25) • HM90 E90AD-M-15 (26) • HM90 F90A-15 (178)

PCD

Recommended Machining Conditions

Grade DOC mm Material Vc m/min Feed mm/tooth Cutting Edge

<2.0 Aluminum alloys <12% silicon 300-3000 0.05-0.25

N ID5 <2.0 Chipboard Fiberboard Plastics 2000-3000 0.05-0.25

<2.0 Copper Brass alloys 500-1500 0.05-0.25

<2.0 Aluminum>12% silicon 250-1000 0.05-0.25 Sharp

N ID8 <2.0 Aluminum<12% silicon 300-3000 0.05-0.25

<2.0 Chipboard Fiberboard Plastics 2000-3000 0.05-0.25

MMC 200-600 0.05-0.25

391