Page 110 - Iscar

P. 110

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

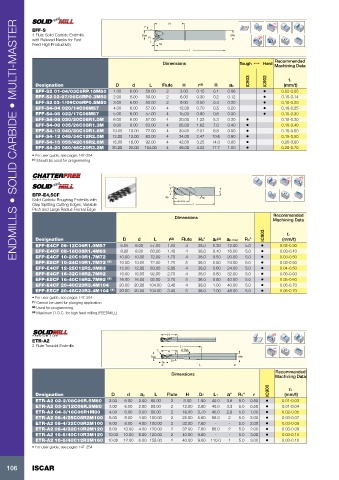

H Rd°

EFF-S 7°

4 Flute Solid Carbide Endmills De9 R dh6

with Relieved Necks for Fast r

Feed High Productivity ap

L

Recommended

Dimensions Tough 1 Hard

Machining Data

IC903 IC902 fz

Designation D d L Flute H r (1) R ap (mm/t)

EFF-S2 01-04/03C6RP.15M50 1.00 6.00 50.00 2 3.00 0.15 0.1 0.06 • 0.02-0.05

EFF-S2 02-07/06C6RP0.3M50 2.00 6.00 50.00 2 6.00 0.30 0.2 0.12 • 0.10-0.14

EFF-S2 03-1/09C06RP0.5M50 3.00 6.00 50.00 2 9.00 0.50 0.4 0.20 • 0.10-0.20

EFF-S4-04 020/14C06M57 4.00 6.00 57.00 4 12.00 0.70 0.5 0.20 • 0.10-0.25

EFF-S4-05 022/17C06M57 5.00 6.00 57.00 4 15.00 0.90 0.6 0.30 • 0.10-0.30

EFF-S4-06 030/20C06R1.0M 6.00 6.00 57.00 4 20.00 1.23 5.3 0.30 • 0.10-0.30

EFF-S4-08 035/26C08R1.3M 8.00 8.00 63.00 4 26.00 1.62 7.0 0.40 • 0.10-0.40

EFF-S4-10 040/30C10R1.6M 10.00 10.00 72.00 4 30.00 2.01 8.8 0.50 • 0.15-0.50

EFF-S4-12 045/34C12R2.0M 12.00 12.00 83.00 4 34.00 2.47 10.6 0.60 • 0.15-0.50

EFF-S4-16 055/42C16R2.6M 16.00 16.00 92.00 4 42.00 3.25 14.0 0.80 • 0.20-0.60

EFF-S4-20 060/46C20R3.2M 20.00 20.00 104.00 4 46.00 4.02 17.7 1.00 • 0.20-0.70

• For user guide, see pages 147-254

(1) Should be used for programming

Rd°

r

D d

EFP-E4,5CF ap

Solid Carbide Roughing Endmills with ap max Ha

Chip Splitting Cutting Edges, Variable L

Pitch and Large Radius Frontal Edge

Recommended

Dimensions

Machining Data

IC903 fz

Designation D d L r (2) Flute Ha° ap (3) ap max Rd° (mm/t)

EFP-E4CF 06-12C06R1.0M57 6.00 6.00 57.00 1.00 4 38.0 0.30 12.00 5.0 • 0.02-0.30

EFP-E4CF 08-16C08R1.4M63 8.00 8.00 63.00 1.40 4 38.0 0.40 16.00 5.0 • 0.03-0.40

EFP-E4CF 10-20C10R1.7M72 10.00 10.00 72.00 1.70 4 38.0 0.50 20.00 5.0 • 0.03-0.50

EFP-E5CF 10-24C10R1.7M72 (1) 10.00 10.00 72.00 1.70 5 38.0 0.50 24.00 5.0 • 0.03-0.50

EFP-E4CF 12-25C12R2.0M83 12.00 12.00 83.00 2.00 4 38.0 0.60 24.00 5.0 • 0.04-0.50

EFP-E4CF 16-32C16R2.7M92 16.00 16.00 92.00 2.70 4 38.0 0.80 32.00 5.0 • 0.05-0.60

EFP-E5CF 16-40C16R2.7M92 (1) 16.00 16.00 92.00 2.70 5 38.0 0.80 40.00 5.0 • 0.05-0.60

EFP-E4CF 20-40C20R3.4M104 20.00 20.00 104.00 3.40 4 38.0 1.00 40.00 5.0 • 0.05-0.70

EFP-E5CF 20-48C20R3.4M104 (1) 20.00 20.00 104.00 3.40 5 38.0 1.00 48.00 5.0 • 0.05-0.70

• For user guide, see pages 147-254

(1) Cannot be used for plunging application

(2) Used for programming

(3) Maximum D.O.C. for high feed milling (FEEDMILL)

H

ETR-A2

2 Flute Toroidal Endmills L1

r a° Ref. Rd°

H

De8 dh6

D2

ap

L

Recommended

Dimensions

Machining Data

IC900 fz

Designation D d ap L Flute H D2 L1 a° Rd° r (mm/t)

ETR-A2 02-2/08C06R.5M80 2.00 6.00 2.00 80.00 2 8.00 1.90 40.0 3.6 5.0 0.50 • 0.01-0.03

ETR-A2 03-2/12C06R.5M80 3.00 6.00 2.00 80.00 2 12.00 2.80 40.0 3.3 5.0 0.50 • 0.01-0.04

ETR-A2 04-3/16C06R1M80 4.00 6.00 3.00 80.00 2 16.00 3.70 40.0 2.8 5.0 1.00 • 0.02-0.05

ETR-A2 06-4/25C08R2M100 6.00 8.00 4.00 100.00 2 25.00 5.60 66.0 2 5.0 2.00 • 0.03-0.07

ETR-A2 08-4/32C08R2M100 8.00 8.00 4.00 100.00 2 32.00 7.60 - - 5.0 2.00 • 0.03-0.09

ETR-A2 08-4/32C10R2M120 8.00 10.00 4.00 120.00 2 32.00 7.60 66.0 2 5.0 2.00 • 0.03-0.09

ETR-A2 10-6/40C10R3M120 10.00 10.00 6.00 120.00 2 40.00 9.60 - - 5.0 3.00 • 0.03-0.10

ETR-A2 10-6/40C12R3M160 10.00 12.00 6.00 158.00 2 40.00 9.60 110.0 1 5.0 3.00 • 0.03-0.10

• For user guide, see pages 147-254

106 ISCAR