Page 69 - Iscar

P. 69

Tsi

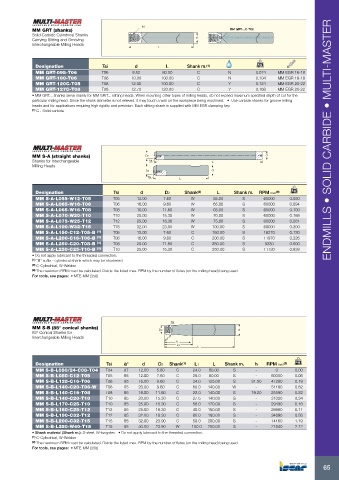

MM GRT (shanks) MM GRT-...C-T08

Solid Carbide Cylindrical Shanks d

Carrying Slitting and Grooving

Interchangeable Milling Heads

L

Designation Tsi d L Shank m. (1) kg

MM GRT-095-T06 T06 9.52 80.00 C N 0.074 MM EGR 16-18

MM GRT-100-T06 T06 10.00 100.00 C N 0.104 MM EGR 16-18

MM GRT-120C-T08 T08 12.00 100.00 C Y 0.124 MM EGR 20-22

MM GRT-127C-T08 T08 12.70 120.00 C Y 0.168 MM EGR 20-22

• MM GRT... shanks serve mainly for MM GRIT... slitting heads. When mounting other types of milling heads, do not exceed maximum specified depth of cut for the

particular milling head. Since the shank diameter is not relieved, it may touch a wall on the workpiece being machined. • Use carbide shanks for groove milling

heads and for applications requiring high rigidity and precision. Each slitting shank is supplied with MM EGR clamping key.

(1) C - Solid carbide

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM S-A (straight shanks) D2 d

Shanks for Interchangeable Tsi L

Milling Heads

d

D2

Tsi L

Designation Tsi d D2 Shank (2) L Shank m. RPM max (3) kg

MM S-A-L055-W12-T05 T05 12.00 7.60 W 55.00 S 60000 0.050

MM S-A-L065-W16-T06 T06 16.00 9.60 W 65.00 S 60000 0.094

MM S-A-L065-W16-T08 T08 16.00 11.60 W 65.00 S 60000 0.100

MM S-A-L070-W20-T10 T10 20.00 15.30 W 70.00 S 60000 0.168

MM S-A-L075-W25-T12 T12 25.00 18.30 W 75.00 S 60000 0.281

MM S-A-L100-W32-T15 T15 32.00 23.90 W 100.00 S 60000 0.300

MM S-A-L150-C12-T05-B (1) T05 12.00 7.60 C 150.00 S 18270 0.130

MM S-A-L200-C16-T06-B (1) T06 16.00 9.60 C 200.00 S 11970 0.326

MM S-A-L250-C20-T08-B (1) T08 20.00 11.60 C 250.00 S 9330 0.600

MM S-A-L250-C25-T10-B (1) T10 25.00 15.30 C 250.00 S 11130 0.938

• Do not apply lubricant to the threaded connection.

(1) "B" suffix - cylindrical shank which may be shortened.

(2) C-Cylindrical, W-Weldon

(3) The maximum RPM must be calculated. Divide the listed max. RPM by the number of flutes (on the milling head) being used.

For tools, see pages: • MTE-MM (358)

Tsi

MM S-B (85° conical shanks) d

85° Conical Shanks for D2

Interchangeable Milling Heads a°

h

L1

L

Designation Tsi a° d D2 Shank (1) L1 L Shank m. h RPM max (2) kg

MM S-B-L080/24-C08-T04 T04 87 12.00 5.80 C 24.0 80.00 S - 0 0.00

MM S-B-L080-C12-T05 T05 85 12.00 7.60 C 25.0 80.00 S - 60000 0.06

MM S-B-L125-C16-T06 T06 85 16.00 9.60 C 34.0 125.00 S 31.50 41280 0.19

MM S-B-L140-C20-T06-W T06 85 20.00 9.60 C 60.0 140.00 W - 51180 0.62

MM S-B-L140-C16-T08 T08 85 16.00 11.60 C 22.0 140.00 S 19.20 25590 0.22

MM S-B-L140-C20-T10 T10 85 20.00 15.30 C 27.5 140.00 S - 31020 0.34

MM S-B-L170-C25-T10 T10 85 25.00 15.30 C 56.0 170.00 S - 29490 0.16

MM S-B-L160-C25-T12 T12 85 25.00 18.30 C 40.0 160.00 S - 28680 0.11

MM S-B-L190-C32-T12 T12 85 32.00 18.30 C 80.0 190.00 S - 34890 0.56

MM S-B-L200-C32-T15 T15 85 32.00 23.90 C 50.0 200.00 S - 14160 1.19

MM S-B-L250-W40-T15 T15 85 40.00 23.90 W 100.0 250.00 S - 21840 2.12

• Shank material (Shank m.): S-steel, W-tungsten. • Do not apply lubricant to the threaded connection.

(1) C-Cylindrical, W-Weldon

(2) The maximum RPM must be calculated. Divide the listed max. RPM by the number of flutes (on the milling head) being used.

For tools, see pages: • MTE-MM (358)

65