Page 68 - Iscar

P. 68

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

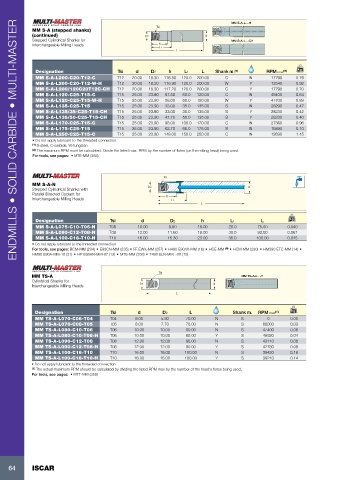

MM S-A-L...-H

MM S-A (stepped shanks) Tsi

(continued) D2 d

Stepped Cylindrical Shanks for MM S-A-L...-CH

Interchangeable Milling Heads h

L1

L

Designation Tsi d D2 h L1 L Shank m. (1) RPM max (2) kg

MM S-A-L200-C20-T12-C T12 20.00 18.30 116.50 120.0 200.00 C N 17790 0.76

MM S-A-L200-C20-T12-W-H T12 20.00 18.30 116.90 120.0 200.00 W Y 12540 0.92

MM S-A-L200/120C20T12C-CH T12 20.00 18.30 117.20 120.0 200.00 C Y 17790 0.70

MM S-A-L120-C25-T15-C T15 25.00 23.90 57.50 60.0 120.00 C N 49400 0.64

MM S-A-L120-C25-T15-W-H T15 25.00 23.90 58.00 60.0 120.00 W Y 41700 0.89

MM S-A-L135-C25-T15 T15 25.00 23.90 33.00 35.0 135.00 S N 28290 0.47

MM S-A-L135/35-C25-T15-CH T15 25.00 23.90 33.00 35.0 135.00 S Y 28230 0.42

MM S-A-L135/50-C25-T15-CH T15 25.00 23.90 47.70 50.0 135.00 S Y 28230 0.40

MM S-A-L170-C25-T15-C T15 25.00 23.90 98.00 100.0 170.00 C N 27360 0.96

MM S-A-L175-C25-T15 T15 25.00 23.90 62.70 65.0 175.00 S N 16890 0.10

MM S-A-L250-C25-T15-C T15 25.00 23.90 148.00 150.0 250.00 C N 12690 1.45

• Do not apply lubricant to the threaded connection.

(1) S-steel, C-carbide, W-tungsten

(2) The maximum RPM must be calculated. Divide the listed max. RPM by the number of flutes (on the milling head) being used.

For tools, see pages: • MTE-MM (358)

Tsi

MM S-A-N d

Stepped Cylindrical Shanks with D2

Parallel Directed Coolant for h

Interchangeable Milling Heads L1

L

Designation Tsi d D2 h L1 L kg

MM S-A-L075-C10-T06-N T06 10.00 9.60 18.00 28.0 75.00 0.040

MM S-A-L090-C12-T08-N T08 12.00 11.60 18.00 30.0 90.00 0.067

MM S-A-L100-C16-T10-N T10 16.00 15.30 23.00 35.0 100.00 0.045

• Do not apply lubricant to the threaded connection

For tools, see pages: BCM-MM (234) • E93CN-MM (235) • FF EWX-MM (257) • H490 E90AX-MM (16) • HCE-MM (9) • HCM-MM (230) • HM390 ETC-MM (14) •

HM90 E90A-MM-10 (21) • HP E90AN-MM-07 (13) • MTE-MM (358) • T490 ELN-MM..-08 (15)

Tsi

MM TS-A MM TS-A-L...-H

Cylindrical Shanks for d

Interchangeable Milling Heads D2

L

Designation Tsi d D2 L Shank m. RPM max (1) kg

MM TS-A-L070-C08-T04 T04 8.00 5.80 70.00 N S 0 0.00

MM TS-A-L070-C08-T05 T05 8.00 7.70 70.00 N S 60000 0.03

MM TS-A-L080-C10-T06 T06 10.00 10.00 80.00 N S 47400 0.06

MM TS-A-L080-C10-T06-H T06 10.00 10.00 80.00 Y S 46920 0.04

MM TS-A-L090-C12-T08 T08 12.00 12.00 90.00 N S 43110 0.08

MM TS-A-L090-C12-T08-H T08 12.00 12.00 90.00 Y S 42780 0.08

MM TS-A-L100-C16-T10 T10 16.00 16.00 100.00 N S 39420 0.16

MM TS-A-L100-C16-T10-H T10 16.00 16.00 100.00 Y S 39210 0.14

• Do not apply lubricant to the threaded connection

(1) The actual maximum RPM should be calculated by dividing the listed RPM max by the number of the head's flutes being used.

For tools, see pages: • MTE-MM (358)

64 ISCAR