Page 687 - Iscar

P. 687

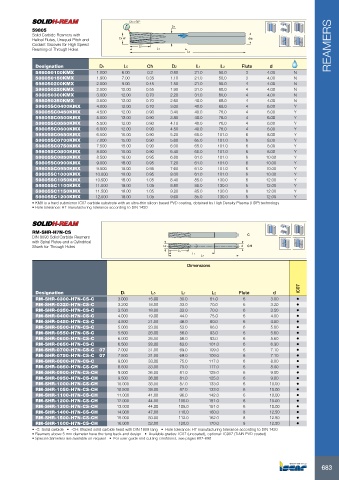

Ch x 60°

59805 D2

Solid Carbide Reamers with

Helical Flutes, Unequal Pitch and Dr H7 dh6

Coolant Grooves for High Speed L5 REAMERS

Reaming of Through Holes L1

L2

Designation Dr L5 Ch D2 L1 L2 Flute d

598050100KMX 1.000 6.00 0.2 0.80 21.0 50.0 3 4.00 N

598050150KMX 1.500 7.00 0.35 1.10 21.0 50.0 3 4.00 N

598050200KMX 2.000 9.00 0.45 1.50 21.0 50.0 4 4.00 N

598050250KMX 2.500 12.00 0.55 1.90 31.0 60.0 4 4.00 N

598050300KMX 3.000 12.00 0.70 2.20 31.0 60.0 4 4.00 N

598050350KMX 3.500 12.00 0.70 2.60 40.0 68.0 4 4.00 N

59805SC0400KMX 4.000 12.00 0.70 3.00 40.0 68.0 4 6.00 Y

59805SC0450KMX 4.500 12.00 0.90 3.40 40.0 76.0 4 6.00 Y

59805SC0500KMX 5.000 12.00 0.90 3.80 40.0 76.0 4 6.00 Y

59805SC0550KMX 5.500 12.00 0.90 4.10 40.0 76.0 4 6.00 Y

59805SC0600KMX 6.000 12.00 0.90 4.50 40.0 76.0 4 6.00 Y

59805SC0650KMX 6.500 15.00 0.90 5.20 65.0 101.0 6 8.00 Y

59805SC0700KMX 7.000 15.00 0.90 5.60 65.0 101.0 6 8.00 Y

59805SC0750KMX 7.500 15.00 0.90 6.00 65.0 101.0 6 8.00 Y

59805SC0800KMX 8.000 15.00 0.90 6.40 65.0 101.0 6 8.00 Y

59805SC0850KMX 8.500 18.00 0.95 6.80 61.0 101.0 6 10.00 Y

59805SC0900KMX 9.000 18.00 0.95 7.20 61.0 101.0 6 10.00 Y

59805SC0950KMX 9.500 18.00 0.95 7.60 61.0 101.0 6 10.00 Y

59805SC1000KMX 10.000 18.00 0.95 8.00 61.0 101.0 6 10.00 Y

59805SC1050KMX 10.500 18.00 1.05 8.40 85.0 130.0 6 12.00 Y

59805SC1100KMX 11.000 18.00 1.05 8.80 85.0 130.0 6 12.00 Y

59805SC1150KMX 11.500 18.00 1.05 9.20 85.0 130.0 6 12.00 Y

59805SC1200KMX 12.000 18.00 1.05 9.60 85.0 130.0 6 12.00 Y

• KMX is a hard submicron IC07 carbide substrate with an ultra-thin silicon based PVD coating, obtained by High Density Plasma (HDP) technology

• Hole tolerance: H7 manufacturing tolerance according to DIN 1420

RM-SHR-H7N-CS C

DIN 8093 Solid Carbide Reamers

with Spiral Flutes and a Cylindrical

Shank for Through Holes Dr d CH

L5

L1

L2

Dimensions

IC07

Designation Dr L5 L1 L2 Flute d

RM-SHR-0300-H7N-CS-C 3.000 15.00 30.0 61.0 6 3.00 •

RM-SHR-0320-H7N-CS-C 3.200 18.00 33.0 70.0 6 3.20 •

RM-SHR-0350-H7N-CS-C 3.500 18.00 33.0 70.0 6 3.50 •

RM-SHR-0400-H7N-CS-C 4.000 19.00 44.0 75.0 6 4.00 •

RM-SHR-0450-H7N-CS-C 4.500 21.00 46.0 80.0 6 4.50 •

RM-SHR-0500-H7N-CS-C 5.000 23.00 53.0 86.0 6 5.00 •

RM-SHR-0550-H7N-CS-C 5.500 26.00 56.0 93.0 6 5.60 •

RM-SHR-0600-H7N-CS-C 6.000 26.00 56.0 93.0 6 5.60 •

RM-SHR-0650-H7N-CS-C 6.500 28.00 63.0 101.0 6 6.30 •

RM-SHR-0700-H7N-CS-C 07 7.000 31.00 69.0 109.0 6 7.10 •

RM-SHR-0750-H7N-CS-C 07 7.500 31.00 69.0 109.0 6 7.10 •

RM-SHR-0800-H7N-CS-C 8.000 33.00 75.0 117.0 6 8.00 •

RM-SHR-0850-H7N-CS-CH 8.500 33.00 75.0 117.0 6 8.00 •

RM-SHR-0900-H7N-CS-CH 9.000 36.00 81.0 125.0 6 9.00 •

RM-SHR-0950-H7N-CS-CH 9.500 36.00 81.0 125.0 6 9.00 •

RM-SHR-1000-H7N-CS-CH 10.000 38.00 87.0 133.0 6 10.00 •

RM-SHR-1050-H7N-CS-CH 10.500 38.00 87.0 133.0 6 10.00 •

RM-SHR-1100-H7N-CS-CH 11.000 41.00 96.0 142.0 6 10.00 •

RM-SHR-1200-H7N-CS-CH 12.000 44.00 105.0 151.0 6 10.00 •

RM-SHR-1300-H7N-CS-CH 13.000 44.00 105.0 151.0 6 10.00 •

RM-SHR-1400-H7N-CS-CH 14.000 47.00 110.0 160.0 8 12.50 •

RM-SHR-1500-H7N-CS-CH 15.000 50.00 112.0 162.0 8 12.50 •

RM-SHR-1600-H7N-CS-CH 16.000 52.00 120.0 170.0 8 12.50 •

• -C: Solid carbide • -CH: Brazed solid carbide head with DIN 1809 tang • Hole tolerance: H7 manufacturing tolerance according to DIN 1420

• Reamers above 5 mm diameter have the tang back-end design • Available grades: IC07 (uncoated), optional: IC907 (TiAlN PVD coated)

• Special diameters are available on request • For user guide and cutting conditions, see pages 687-690

683