Page 691 - Iscar

P. 691

USER GUIDE

REAMERS

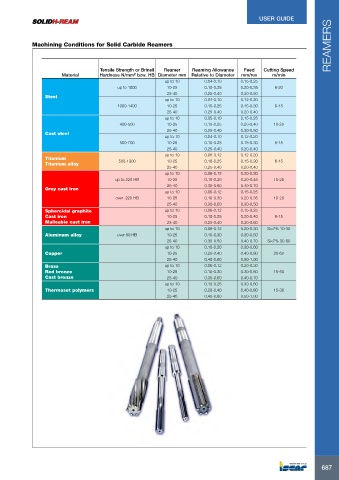

Machining Conditions for Solid Carbide Reamers

Tensile Strength or Brinell Reamer Reaming Allowance Feed Cutting Speed

Material Hardness N/mm bzw. HB Diameter mm Relative to Diameter mm/rev m/min

2

up to 10 0.04-0.10 0.15-0.25

up to 1000 10-25 0.10-0.25 0.20-0.35 6-20

25-40 0.25-0.40 0.30-0.50

Steel

up to 10 0.04-0.10 0.12-0.20

1000-1400 10-25 0.10-0.25 0.15-0.30 6-15

25-40 0.25-0.40 0.20-0.40

up to 10 0.05-0.10 0.15-0.25

400-500 10-25 0.10-0.25 0.20-0.40 10-20

25-40 0.25-0.40 0.30-0.50

Cast steel

up to 10 0.04-0.10 0.12-0.20

500-700 10-25 0.10-0.25 0.15-0.30 6-15

25-40 0.25-0.40 0.20-0.40

up to 10 0.06-0.12 0.12-0.20

Titanium 500-1300 10-25 0.10-0.25 0.15-0.30 6-15

Titanium alloy

25-40 0.25-0.40 0.20-0.40

up to 10 0.06-0.12 0.20-0.30

up to 220 HB 10-25 0.10-0.30 0.30-0.45 10-25

25-40 0.30-0.50 0.40-0.70

Grey cast iron

up to 10 0.06-0.12 0.15-0.25

over 220 HB 10-25 0.10-0.30 0.20-0.35 10-20

25-40 0.30-0.50 0.30-0.50

Spheroidal graphite up to 10 0.06-0.12 0.15-0.25

Cast iron 10-25 0.10-0.25 0.20-0.40 8-15

Malleable cast iron 25-40 0.25-0.40 0.30-0.60

up to 10 0.06-0.12 0.20-0.30 Si<7% 10-30

Aluminum alloy over 80 HB 10-25 0.10-0.30 0.30-0.50

25-40 0.30-0.50 0.40-0.70 Si<7% 30-60

up to 10 0.10-0.20 0.30-0.60

Copper 10-25 0.20-0.40 0.40-0.80 20-60

25-40 0.40-0.60 0.50-1.00

Brass up to 10 0.06-0.12 0.20-0.30

Red bronze 10-25 0.10-0.30 0.30-0.50 15-50

Cast bronze 25-40 0.30-0.50 0.40-0.70

up to 10 0.10-0.25 0.30-0.60

Thermoset polymers 10-25 0.20-0.40 0.40-0.80 15-30

25-40 0.40-0.60 0.50-1.00

687

687