Page 685 - Iscar

P. 685

USER GUIDE

REAMERS

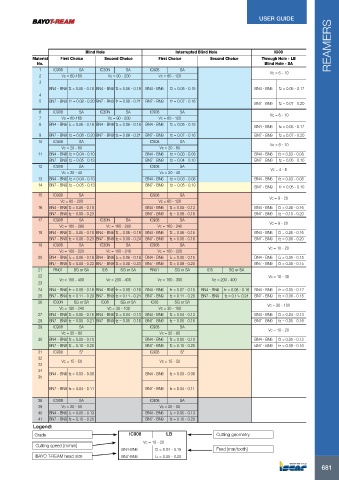

Recommeded Cutting Conditions for BAYO T-REAM High Speed Reaming Heads

Through Hole Interrupted Through Hole Blind Hole Interrupted Blind Hole IC08

ISO Material Condition Material First Choice Second Choice First Choice Second Choice Material First Choice Second Choice First Choice Second Choice Through Hole - LB

No. (1) No. Blind Hole - SA

Annealed 1 IC908 LB IC30N LA IC908 LB IC908 SA 1 IC908 SA IC30N SA IC908 SA Vc = 6 - 10

Annealed 2 Vc = 80 - 200 Vc = 90 - 240 Vc = 60 - 120 Vc = 60 - 120 2 Vc = 60-160 Vc = 90 - 200 Vc = 60 - 120

Non-alloyed Quenched & 3 3

steel, cast steel, tempered BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.15 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.15 BN4 - BN6 fz = 0.05 - 0.17

free cutting steel

Annealed 4 4

Quenched & 5 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.09 - 0.21 BN7 - BN9 fz = 0.07 - 0.16 5 BN7 - BN9 fz = 0.08 - 0.20 BN7 - BN9 fz = 0.08 - 0.21 BN7 - BN9 fz = 0.07 - 0.16 BN7 - BN9 fz = 0.07 - 0.20

tempered

Annealed 6 IC908 LB IC30N LA IC908 LB IC908 SA 6 IC908 SA IC30N SA IC908 SA

Low alloyed Vc = 6 - 10

steel, 7 Vc = 80 - 200 Vc = 90 - 240 Vc = 60 - 120 Vc = 60 - 120 7 Vc = 60-160 Vc = 90 - 200 Vc = 60 - 120

P cast steel (less Quenched & 8 BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.15 8 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.15

than 5% alloying tempered BN4 - BN6 fz = 0.05 - 0.17

elements)

9 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.09 - 0.21 BN7 - BN9 fz = 0.07 - 0.16 9 BN7 - BN9 fz = 0.08 - 0.20 BN7 - BN9 fz = 0.08 - 0.21 BN7 - BN9 fz = 0.07 - 0.16 BN7 - BN9 fz = 0.07 - 0.20

10 IC908 LB IC908 SA IC908 LB IC908 SA 10 IC908 SA IC908 SA

High alloyed Annealed Vc = 20 - 60 Vc = 20 - 60 Vc = 20 - 60 Vc = 20 - 60 Vc = 20 - 60 Vc = 20 - 60 Vc = 6 - 10

steel, cast steel,

and tool steel Quenched & 11 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.03 - 0.09 11 BN4 - BN6 fz = 0.04 - 0.10 BN4 - BN6 fz = 0.03 - 0.08 BN4 - BN6 fz = 0.03 - 0.08

tempered BN7 - BN9 fz = 0.07 - 0.17 BN7 - BN9 fz = 0.06 - 0.14 BN7 - BN9 fz = 0.05 - 0.14 BN7 - BN9 fz = 0.04 - 0.11 BN7 - BN9 fz = 0.05 - 0.13 BN7 - BN9 fz = 0.04 - 0.10 BN7 - BN9 fz = 0.05 - 0.10

12 IC908 LB IC908 SA IC908 LB IC908 SA 12 IC908 SA IC908 SA

Ferritic / martensitic Vc = 4 - 8

Stainless steel Vc = 20 - 40 Vc = 20 - 40 Vc = 20 - 40 Vc = 20 - 40 Vc = 20 - 40 Vc = 20 - 40

Martensitic 13 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.03 - 0.09 13 BN4 - BN6 fz = 0.04 - 0.10 BN4 - BN6 fz = 0.03 - 0.08 BN4 - BN6 fz = 0.03 - 0.08

M Stainless steel Austentic 14 BN7 - BN9 fz = 0.07 - 0.17 BN7 - BN9 fz = 0.06 - 0.14 BN7 - BN9 fz = 0.05 - 0.14 BN7 - BN9 fz = 0.04 - 0.11 14 BN7 - BN9 fz = 0.05 - 0.13 BN7 - BN9 fz = 0.05 - 0.10 BN7 - BN9 fz = 0.05 - 0.10

15 IC908 LB IC908 SA IC908 LB IC908 SA 15 IC908 SA IC908 SA

Ferritic Vc = 8 - 20

Grey iron Vc = 120 - 220 Vc = 120 - 220 Vc = 80 - 200 Vc = 80 - 200 Vc = 80 - 200 Vc = 60 - 120

(GG) 16 BN4 - BN6 fz = 0.08 - 0.18 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.05 - 0.13 16 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.08 - 0.16

Pearlitic

BN7 - BN9 fz = 0.10 - 0.24 BN7 - BN9 fz = 0.10 - 0.22 BN7 - BN9 fz = 0.07 - 0.17 BN7 - BN9 fz = 0.07 - 0.17 BN7 - BN9 fz = 0.08 - 0.23 BN7 - BN9 fz = 0.08 - 0.18 BN7 - BN9 fz = 0.10 - 0.20

17 IC908 SA or LB IC30N LA IC908 LB IC908 SA 17 IC908 SA IC30N SA IC908 SA

Pearlitic / ferritic Vc = 9 - 20

K Nodular iron Vc = 160 - 280 Vc = 160 - 300 Vc = 150 - 250 Vc = 150 - 250 Vc = 160 - 280 Vc = 160 - 280 Vc = 160 - 240

(GGG)

Pearlitic / martensitic 18 BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.06 - 0.15 18 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.06 - 0.16 BN4 - BN6 fz = 0.06 - 0.16

BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.08 - 0.19 BN7 - BN9 fz = 0.08 - 0.19 BN7 - BN9 fz = 0.08 - 0.23 BN7 - BN9 fz = 0.08 - 0.24 BN7 - BN9 fz = 0.08 - 0.18 BN7 - BN9 fz = 0.08 - 0.20

19 IC908 SA or LB IC30N LA or SA IC908 LB IC908 SA 19 IC908 SA IC30N SA IC908 SA

Malleable iron, Ferritic Vc = 100 - 220 Vc = 100 - 240 Vc = 100 - 220 Vc = 100 - 220 Vc = 100 - 220 Vc = 100 - 240 Vc = 100 - 220 Vc = 10 - 20

Nodular iron

ferritic / pearlitic Pearlitic 20 BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.06 - 0.15 20 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.15 BN4 - BN6 fz = 0.05 - 0.15

BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.08 - 0.20 BN7 - BN9 fz = 0.08 - 0.19 BN7 - BN9 fz = 0.08 - 0.23 BN7 - BN9 fz = 0.08 - 0.23 BN7 - BN9 fz = 0.08 - 0.20 BN7 - BN9 fz = 0.08 - 0.15

Aluminum Not cureable 21 RN01 LB or SG ID5 SG RN01 LB ID5 SG 21 RN01 SG or SA ID5 SG or SA RN01 SG or SA ID5 SG or SA

wrought alloy Cured 22 22 Vc = 10 - 30

Not cureable 23 Vc = 150 - 400 Vc = 200 - 500 Vc = 150 - 350 Vc = 200 - 500 23 Vc = 150 - 400 Vc = 200 - 400 Vc = 150 - 300 Vc = 200 - 400

Aluminum - cast, Cured 24 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.08 - 0.2 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.08 - 0.2 24 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.07 - 0.15 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.05 - 0.12

alloyed

High temperature 25 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.11 - 0.24 25 BN7 - BN9 fz = 0.11 - 0.20 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.11 - 0.20 BN7 - BN9 fz = 0.11- 0.24 BN7 - BN9 fz = 0.08 - 0.15

26 IC30N SA or SG IC08 SG or SA IC08 SG or SA 26 IC30N SG or SA IC08 SG or SA IC08 SG or SA

N Copper alloys Free cutting Vc = 180 - 240 Vc = 30 - 100 Vc = 30 - 100 Vc = 180 - 240 Vc = 30 - 100 Vc = 30 - 100 Vc = 30 - 100

Brass, bronze Brass 27 BN4 - BN6 fz = 0.05 - 0.16 BN4 - BN6 fz = 0.04 - 0.13 BN4 - BN6 fz = 0.04 - 0.13 27 BN4 - BN6 fz = 0.05 - 0.16 BN4 - BN6 fz = 0.04 - 0.13 BN4 - BN6 fz = 0.04 - 0.13 BN4 - BN6 fz = 0.04 - 0.13

Electrolitic copper 28 BN7 - BN9 fz = 0.04 - 0.20 BN7 - BN9 fz = 0.05 - 0.16 BN7 - BN9 fz = 0.05 - 0.16 28 BN7 - BN9 fz = 0.05 - 0.21 BN7 - BN9 fz = 0.05 - 0.16 BN7 - BN9 fz = 0.05 - 0.16 BN7 - BN9 fz = 0.05 - 0.16

Duroplastics, fiber 29 IC908 SA IC908 LB IC908 SA IC908 LB 29 IC908 SA IC908 SA Vc = 10 - 20

plastics Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80

Non-metallic 30 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.12 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.12 30 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.12

Hard rubber

BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.23 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.23 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.08 - 0.16

Annealed 31 IC908 L * IC908 S* IC908 L* IC908 S* 31 IC908 S* IC908 S*

* High temp. Cured 32 Vc = 15 - 50 Vc = 15 - 50 Vc = 15 - 50 Vc = 15 - 50 32 Vc = 15 - 50 Vc = 15 - 50

Annealed 33 33

S alloys Cured 34 BN4 - BN6 fz = 0.04 - 0.10 BN4 - BN6 fz = 0.04 - 0.10 BN4 - BN6 fz = 0.03 - 0.08 BN4 - BN6 fz = 0.03 - 0.08 34 BN4 - BN6 fz = 0.03 - 0.08 BN4 - BN6 fz = 0.03 - 0.08

Cast 35 35

BN7 - BN9 fz = 0.05 - 0.13 BN7 - BN9 fz = 0.05 - 0.13 BN7 - BN9 fz = 0.04 - 0.11 BN7 - BN9 fz = 0.04 - 0.11 BN7 - BN9 fz = 0.04 - 0.11 BN7 - BN9 fz = 0.04 - 0.11

Hardened 38 IC908 LB IC908 SA IC908 LB IC908 SA 38 IC908 SA IC908 SA

Vc = 25 - 50

Vc = 25 - 50

Vc = 25 - 50

Vc = 25 - 50

Vc = 25 - 50

Vc = 25 - 50

H Hardened steel Hardened 39 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.05 - 0.13 39 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.05 - 0.13

40

Cast

40

Hardened 41 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20 41 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20

Legend:

Grade IC908 LB Cutting geometry

Vc = 10 - 20

Cutting speed [m/min]

BN4-BN6 fz = 0.04 - 0.15 Feed [mm/tooth]

BAYO T-REAM head size BN7-BN9 fz = 0.05 - 0.20

681

681