Page 640 - Iscar

P. 640

USER GUIDE

DEEP HOLE DRILLING

Technical Information -

Cutting Fluid Management

Successful deep hole drilling can be achieved not only

by tooling but also by an optimized combination of the Heat dissipation

tool, the machine and the cutting fluid. The cutting fluid The coolability of cutting fluid depends on thermal

is one of the essential components to obtain safe, stable characteristics such as thermal conductivity and specific

and cost efficient deep hole drilling. Therefore, it is very heat. The cutting fluid of good coolability increases

important to choose and use the cutting tool life, but a water-soluble type is not preferred in

fluid correctly. deep hole drilling because of a lesser lubrication effect.

If water-soluble fluid is used, the concentration is

Cutting Fluid recommended to be 10% (dilution rate 1/10) or more.

The cutting fluid plays a large role in lubrication of the Cooling of chips is important as well as cooling of

tool, cooling of cutting edges and chips and evacuation cutting edges and guide pads in deep hole drilling.

of chips in deep hole drilling. It also contributes to Temperature control is also important to maintain long

improved tool life, surface finish and cutting accuracy tool life, stable cutting conditions and cutting accuracy.

when being fed continuously during cutting.

Chip evacuation

Lubrication Cutting fluid has an important role in deep hole drilling

Lubrication of cutting edges and guide pads is as it evacuates chips through to the back end of boring

necessary in deep hole drilling. To get efficient bar (for STS) or inner tube (for DTS), whereas it finishes

lubrication, it is recommended to use EP (Extreme its role as soon as the chips are separated from the

Pressure) additives that contain sulfur or chlorine. workpiece in general cutting. It is also important to

control the flow and the pressure of cutting fluid.

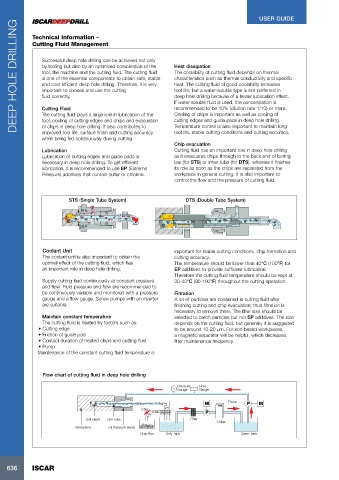

STS (Single Tube System) DTS (Double Tube System)

Coolant Unit important for stable cutting conditions, chip formation and

The coolant unit is also important to obtain the cutting accuracy.

optimal effect of the cutting fluid, which has The temperature should be lower than 40°C (100°F) for

an important role in deep hole drilling. EP additives to provide sufficient lubrication.

Therefore the cutting fluid temperature should be kept at

Supply cutting fluid continuously at constant pressure 30-40°C (90-100°F) throughout the cutting operation.

and flow. Fluid pressure and flow are recommended to

be continuously variable and monitored with a pressure Filtration

gauge and a flow gauge. Screw pumps with an inverter A lot of particles are contained in cutting fluid after

are suitable. finishing cutting and chip evacuation; thus filtration is

necessary to remove them. The filter size should be

Maintain constant temperature selected to catch particles but not EP additives. The size

The cutting fluid is heated by factors such as: depends on the cutting fluid, but generally it is suggested

• Cutting edge to be around 10-20 μm. For iron-based workpieces,

• Friction of guide pad a magnetic separator will be helpful, which decreases

• Contact duration of heated chips and cutting fluid filter maintenance frequency.

• Pump

Maintenance of the constant cutting fluid temperature is

Flow chart of cutting fluid in deep hole drilling

Pressure Flow

Gauge Gauge

M Pump P M

Chip

P

Drill Head Drill Tube Filter

Chiller

Workpiece Oil Pressure Head

Chip Box Dirty Tank Clean Tank

ISCAR

636 ISCAR

636