Page 388 - Iscar

P. 388

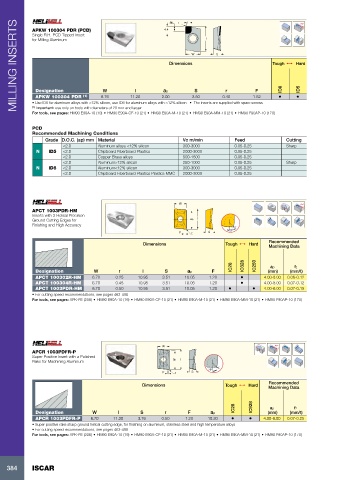

MILLING INSERTS APKW 100304 PDR (PCD) 4.4 Dimensions W l S Tough 1 Hard

F

r

ap

Rd°

Single R.H. PCD Tipped Insert

for Milling Aluminum

ID5

ID8

r

W

S

Designation

l

F

ap

(1)

2.00

APKW 100304 PDR

6.76

11.20

0.40

3.50

1.52

• Use ID5 for aluminum alloys with <12% silicon, use ID8 for aluminum alloys with >12% silicon • The inserts are supplied with spare screws

(1) Important: use only on tools with diameters of 20 mm and larger

For tools, see pages: HM90 E90A-10 (19) • HM90 E90A-CF-10 (21) • HM90 E90A-M-10 (21) • HM90 E90A-MM-10 (21) • HM90 F90AP-10 (170) • •

PCD

Recommended Machining Conditions

Grade D.O.C. (ap) mm Material Vc m/min Feed Cutting

<2.0 Aluminum alloys <12% silicon 300-3000 0.05-0.25 Sharp

N ID5 <2.0 Chipboard Fiberboard Plastics 2000-3000 0.05-0.25

<2.0 Copper Brass alloys 500-1500 0.05-0.25

<2.0 Aluminum>12% silicon 250-1000 0.05-0.25 Sharp

N ID8 <2.0 Aluminum<12% silicon 300-3000 0.05-0.25

<2.0 Chipboard Fiberboard Plastics Plastics MMC 2000-3000 0.05-0.25

W Rd°

APCT 1003PDR-HM

Inserts with 2 Helical Precision

Ground Cutting Edges for ap I

Finishing and High Accuracy r

25°

F r S

Recommended

Dimensions Tough 1 Hard Machining Data

IC28 IC328 IC250 ap fz

Designation W r l S ap F (mm) (mm/t)

APCT 100302R-HM 6.70 0.25 10.95 3.51 10.05 1.20 • 4.00-8.00 0.06-0.12

APCT 100304R-HM 6.70 0.45 10.95 3.51 10.05 1.20 • 4.00-8.00 0.07-0.12

APCT 1003PDR-HM 6.70 0.50 10.95 3.51 10.05 1.20 • • 4.00-8.00 0.07-0.15

• For cutting speed recommendations, see pages 462-498

For tools, see pages: APK-FE (208) • HM90 E90A-10 (19) • HM90 E90A-CF-10 (21) • HM90 E90A-M-10 (21) • HM90 E90A-MM-10 (21) • HM90 F90AP-10 (170)

W Rd°

APCR 1003PDFR-P

Super Positive Insert with a Polished I

Rake for Machining Aluminum ap

r

25°

F r S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC28 IC928 ap fz

Designation W l S r F ap (mm) (mm/t)

APCR 1003PDFR-P 6.70 11.20 3.76 0.50 1.20 10.30 • • 4.00-8.00 0.07-0.25

• Super positive rake sharp ground helical cutting edge, for finishing on aluminum, stainless steel and high temperature alloys

• For cutting speed recommendations, see pages 462-498

For tools, see pages: APK-FE (208) • HM90 E90A-10 (19) • HM90 E90A-CF-10 (21) • HM90 E90A-M-10 (21) • HM90 E90A-MM-10 (21) • HM90 F90AP-10 (170)

384 ISCAR