Page 386 - Iscar

P. 386

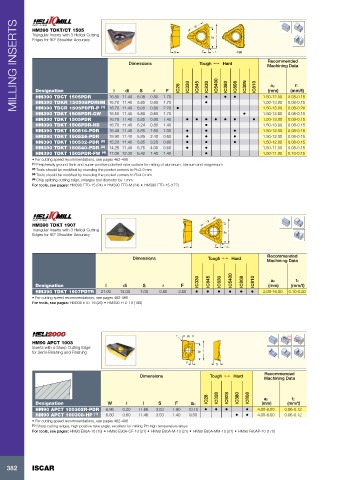

MILLING INSERTS HM390 TDKT/CT 1505 Dimensions S IC28 IC330 di IC845 Tough 1 Hard -FW IC30N IC810 Machining Data

Triangular Inserts with 3 Helical Cutting

l

ap

Edges for 90° Shoulder Accuracy

F

r

Recommended

IC5400

IC808

IC380

IC830

fz

ap

(mm/t)

r

F

S

di

l

(mm)

Designation

HM390 TDCT 1505PDR

•

5.85

HM390 TDKR 150508PDRHM 16.70 11.40

0.80

1.50-13.00

1.70

0.08-0.15

2.20 •

16.70 11.40

1.50-13.00

0.80

0.08-0.20

6.00

HM390 TDCR 1505PDFR-P

HM390 TDKT 1505PDR-GW (1) 16.80 11.40 6.08 0.80 1.70 • • • • 1.50-12.00 0.08-0.15

0.80

0.08-0.15

5.80

16.50 11.40

1.70

1.50-13.00

HM390 TDKT 1505PDR 16.70 11.40 5.85 0.80 1.40 • • • • • • • 1.50-13.00 0.08-0.15

HM390 TDKT 1505PDR-HS 16.70 11.40 6.24 0.80 1.40 • 1.50-13.00 0.08-0.15

HM390 TDKT 150516-PDR 16.40 11.40 5.85 1.60 1.00 • • • 1.50-12.50 0.08-0.15

HM390 TDKT 150524-PDR 15.90 11.40 5.85 2.40 0.60 • • • 1.50-12.00 0.08-0.15

HM390 TDKT 150532-PDR (2) 15.20 11.40 5.85 3.20 0.60 • • • 1.50-12.00 0.08-0.15

HM390 TDKT 150540-PDR (3) 14.25 11.40 5.75 4.00 0.60 • • 1.50-11.00 0.08-0.15

HM390 TDKT 1505PDR-FW (4) 17.06 12.30 6.42 1.40 1.40 • 1.50-11.00 0.10-0.15

• For cutting speed recommendations, see pages 462-498

(1) Peripherally ground flank and super positive polished rake surface for milling of aluminum, titanium and magnesium

(2) Tools should be modified by rounding the pocket corners to R=2.0 mm

(3) Tools should be modified by rounding the pocket corners to R=4.0 mm

(4) Chip splitting cutting edge, enlarges tool diameter by 1 mm

For tools, see pages: HM390 ETD-15 (24) • HM390 ETD-M (24) • HM390 FTD-15 (177)

HM390 TDKT 1907 di

Triangular Inserts with 3 Helical Cutting l

Edges for 90° Shoulder Accuracy ap

S F r

Recommended

Dimensions Tough 1 Hard Machining Data

IC330 IC845 IC830 IC5400 IC808 IC810 ap fz

Designation l di S r F (mm) (mm/t)

HM390 TDKT 1907PDTR 21.00 14.00 7.00 0.80 2.50 • • • • • • 2.00-16.00 0.10-0.20

• For cutting speed recommendations, see pages 462-498

For tools, see pages: HM390 ETD-19 (26) • HM390 FTD-19 (180)

r W Rd°

HM90 APCT 1003

Inserts with a Sharp Cutting Edge

for Semi-Finishing and Finishing ap l

F S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC28 IC328 IC928 IC380 IC808 ap fz

Designation W r l S F ap (mm) (mm/t)

HM90 APCT 100302R-PDR 6.96 0.20 11.66 3.53 1.90 10.10 • • • • 4.00-8.00 0.06-0.12

HM90 APCT 100308-HP (1) 6.80 0.80 11.46 3.53 1.40 9.50 • • 4.00-8.00 0.06-0.12

• For cutting speed recommendations, see pages 462-498

(1) Sharp cutting edges, high positive rake angle, excellent for milling PH high temperature alloys

For tools, see pages: HM90 E90A-10 (19) • HM90 E90A-CF-10 (21) • HM90 E90A-M-10 (21) • HM90 E90A-MM-10 (21) • HM90 F90AP-10 (170)

382 ISCAR