Page 9 - UNION

P. 9

part. GRADE INFORMATION part.

A A

turning turning

& PCBN / PCD &

Milling Milling

Union PCBN is an ultra hard cutting tool consisting of polycrystalline cubic boron nitride with metallic or

ceramic binder. It is available both tip brazed and solid CBN. Recommended Cutting Conditions

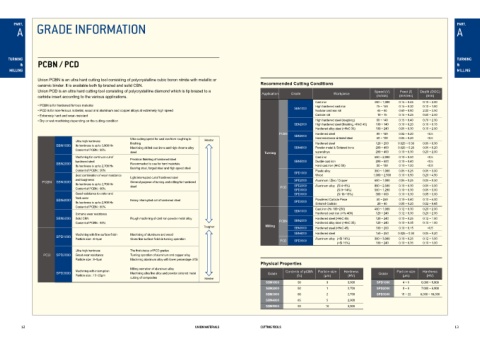

Union PCD is an ultra hard cutting tool consisting of polycrystalline diamond which is tip brazed to a Application Grade Workpiece Speed (V) Feed (f) Depth (DOC)

carbide insert according to the various applications. (m/min) (mm/rev) (mm)

Cast iron 400 ~ 1,000 0.15 ~ 0.45 0.10 ~ 2.00

• PCBN is for hardened ferrous material High hardened cast iron 75 ~ 150 0.15 ~ 0.30 0.10 ~ 1.80

• PCD is for non-ferrous material, wood and aluminum and copper alloys at extremely high speed SBN1000 Nodular cast iron roll 45 ~ 60 0.60 ~ 0.80 2.00 ~ 3.50

• Extremely hard and wear-resistant Carbide roll 10 ~ 15 0.15 ~ 0.25 0.50 ~ 2.50

• Dry or wet machining depending on the cutting condition High hardened steel (roughing) 60 ~ 140 0.15 ~ 0.40 0.70 ~ 2.30

SBN2000 High hardened steel (finishing, >HRC 45) 100 ~ 140 0.10 ~ 0.20 0.10 ~ 0.75

Hardened alloy steel (>HRC 35) 100 ~ 240 0.05 ~ 0.30 0.10 ~ 2.50

PCBN SBN3000 Hardened steel 80 ~ 160 0.02 ~ 0.20 <0.5

Ultra cutting speed for cast iron from roughing to Heat resistance sintered steel 50 ~ 100 0.05 ~ 0.20 <0.5

Ultra high hardness Harder

SBN1000 Its hardness is up to 3,900 Hv finishing SBN4000 Hardened steel 120 ~ 250 0.025 ~ 0.50 0.05 ~ 0.30

0.05 ~ 0.20

200 ~ 400

Powder metal & Sintered irons

0.025 ~ 0.20

Content of PCBN : 95% Machining chilled cast irons and high chrome alloy

steel Turning superalloys 200 ~ 400 0.10 ~ 0.30 0.20 ~ 2.00

Machining for continuos cut of Precision finishing of hardened steel Cast iron 500 ~ 2,000 0.10 ~ 0.50 <0.5

hardened steel SBN5000 Ductile cast iron 200 ~ 600 0.10 ~ 0.40 <0.5

SBN2000 Recommeded to use for hard materials

Its hardness is up to 2,700 Hv Bearing steel, forged steel and high speed steel Hard cast iron (HRC 59) 50 ~ 150 0.10 ~ 1.00 <0.5

Content of PCBN : 50% SPD1000 Plastic alloy 300 ~ 1,000 0.05 ~ 0.25 0.05 ~ 3.00

Best combination of wear resistance Wood 1,000 ~ 2,500 0.10 ~ 0.50 0.20 ~ 4.50

and toughness Light interrupted cut of hardened steel SPD2000 Aluminum / Zinc / Copper 600 ~ 1,000 0.05 ~ 0.25 0.05 ~ 0.30

PCBN SBN3000 General purpose of turning and milling for hardened

Its hardness is up to 2,700 Hv SPD2000 Aluminum alloy (Si 4~8%) 800 ~ 2,500 0.10 ~ 0.30 0.05 ~ 3.00

Content of PCBN : 60% steel PCD SPD3000 (Si 9~14%) 500 ~ 1,290 0.10 ~ 0.30 0.05 ~ 3.00

Good resistance to crater and SPD3000 (Si 16~18%) 300 ~ 600 0.10 ~ 0.30 0.05 ~ 3.00

flank wear

SBN4000 Heavy interrupted cut of hardened steel SPD3000 Powdered Carbide Piece 50 ~ 250 0.10 ~ 0.40 0.10 ~ 4.00

Its hardness is up to 2,900 Hv Sintered Carbide 20 ~ 40 0.05 ~ 0.20 0.02 ~ 0.45

Content of PCBN : 65% Cast iron (HB 180~230) 400 ~ 1,000 0.12 ~ 0.30 0.20 ~ 2.00

SBN1000

Extreme wear resistance Hardened cast iron (>HB 400) 120 ~ 240 0.12 ~ 0.30 0.20 ~ 2.00

SBN5000 Solid CBN Rough machining of cast iron powder metal alloy Hardened steel (>HRC 45) 120 ~ 240 0.10 ~ 0.25 0.12 ~ 1.00

Content of PCBN : 93% PCBN SBN2000 Hardened alloy steel (>HRC 35) 120 ~ 240 0.10 ~ 0.35 0.10 ~ 1.00

Tougher Milling SBN3000 Hardened steel (>HRC 45) 100 ~ 200 0.10 ~ 0.15 <0.5

Machining with fine surface finish Machining of aluminum and wood SBN4000 Hardened steel 150 ~ 250 0.025 ~ 0.30 0.05 ~ 0.20

SPD1000

Particle size : 4~5μm Gives fine surface finish in turning operation Aluminum alloy (<Si 14%) 300 ~ 3,000 0.10 ~ 0.25 0.12 ~ 1.00

PCD SPD3000

(>Si 15%) 100 ~ 240 0.10 ~ 0.35 0.10 ~ 1.00

Ultra high hardness The first choice of PCD grades

PCD SPD2000 Great wear resistance Turning operation of aluminum and copper alloy

Particle size : 8~9μm Machining aluminum alloy with lower percentage of Si

Physical Properties

Milling operation of aluminum alloy

Machining with interruption Contents of pCBN Particle size Hardness Particle size Hardness

SPD3000 Machining ultra fine alloy and powder sintered metal Grade Grade

Particle size : 15~22μm (%) (μm) (HV) (μm) (HV)

cutting of composites Harder

SBN1000 95 3 3,900 SPD1000 4 ~ 5 6,000 ~ 8,000

SBN2000 50 1 2,700 SPD2000 8 ~ 9 7,000 ~ 9,000

SBN3000 60 2 2,700 SPD3000 15 ~ 22 8,000 ~ 10,000

SBN4000 65 5 2,900

SBN5000 93 10 3,900

12 union Materials cutting tools 13