Page 8 - UNION

P. 8

part. GRADE INFORMATION part.

A A

CErMET

turning turning

& A matrix of TiCN with carbide as a metal binder, Union Cermets are tougher than ceramics and harder &

Milling than tungsten carbides. It shows greater wear resistance than carbide and its cutting speed is also much Milling

higher than carbide. Cermet inserts give excellent surface finish and high-speed machining.

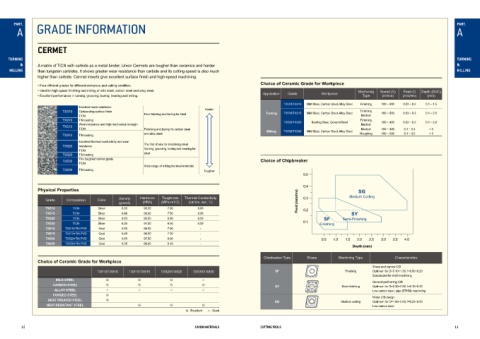

Choice of Ceramic Grade for Workpiece

• Four different grades for different workpiece and cutting condition.

• Ideal for high-speed finishing and milling of mild steel, carbon steel and alloy steel. Machining Speed (V) Feed (f) Depth (DOC)

• Excellent performance in turning, grooving, boring, bearing and milling. Application Grade Workpiece Type (m/min) (mm/rev) (mm)

TX510/TX910 Mild Steel, Carbon Steel, Alloy Steel Finishing 100 ~ 600 0.03 ~ 0.3 0.1 ~ 1.5

Excellent wear resistance

TX510 Outstanding surface finish Harder Turning TX515/TX915 Mild Steel, Carbon Steel, Alloy Steel Finishing 100 ~ 500 0.03 ~ 0.3 0.1 ~ 2.0

TiCN Fine-finishing and boring for steel Medium

TX910 TiN coating TX520/TX920 Bearing Steel, General Steel Finishing 100 ~ 400 0.03 ~ 0.3 0.1 ~ 2.0

Wear resistance and high mechanical strength Medium

TX515

TiCN Finishing and boring for carbon steel Milling TX530/TX930 Mild Steel, Carbon Steel, Alloy Steel Medium 100 ~ 400 0.1 ~ 0.3 < 5

TX915 TiN coating and alloy steel Roughing 100 ~ 500 0.1 ~ 0.5 < 3

Excellent thermal conductivity and wear

TX520 resistance The first choice for machining steel

TiCN Turning, grooving, boring and bearing for

TX920 TiN coating steel

The toughest cermet grade

TX530 Choice of Chipbreaker

TiCN

Wide range of milling for steel materials

TX930 TiN coating Tougher

0.5

0.4

Physical Properties SG

Grade Composition Color Density Hardness Toughness Thermal Conductivity 0.3 Medium Cutting

(g/cm3) (HRA) (MPa·m1/2) (cal/cm. sec. ℃) Feed (mm/rev)

TX510 TiCN Silver 6.50 93.50 7.00 0.08 0.2

TX515 TiCN Silver 6.48 93.00 7.50 0.08 SY

TX520 TiCN Silver 6.53 92.50 8.00 0.09 SF Semi-Finishing

TX530 TiCN Silver 6.35 91.00 8.40 0.09 0.1 Finishing

TX910 TX510+TiN PVD Gold 6.50 98.50 7.00 -

TX915 TX515+TiN PVD Gold 6.48 98.00 7.50 -

TX920 TX520+TiN PVD Gold 6.53 97.50 8.00 - 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

TX930 TX530+TiN PVD Gold 6.35 96.00 8.40 -

Depth (mm)

Chipbreaker Type Shape Machining Type Characteristics

Choice of Ceramic Grade for Workpiece

Sharp and narrow C/B

TX510/TX910 TX515/TX915 TX520/TX920 TX530/TX930 SF Finishing Optimum for D=0.10~1.50, f=0.05~0.20

Specialized for shaft machining

MILD STEEL ◎ ◎ ◎ ○ General performing C/B

CARBON STEEL ◎ ◎ ◎ ◎ SY Semi-finishing Optimum for D=0.30~2.50, f=0.10~0.30

ALLOY STEEL ○ ○ ○ ○ Low carbon steel, pipe (STKM) machining

FORGED STEEL ◎ Wider C/B design

HEAT TREATED STEEL ◎ SG Medium cutting Optimum for D=1.00~5.00, f=0.20~0.50

HEAT RESISTANT STEEL ◎ ◎ ◎ Low carbon steel

◎ : Excellent ○ : Good

10 union Materials cutting tools 11