Page 7 - UNION

P. 7

part. GRADE INFORMATION part.

A A

turning turning

& &

Milling Milling

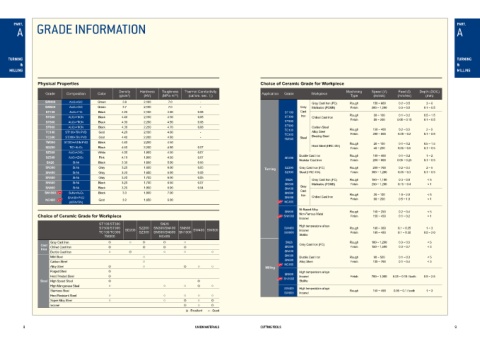

Physical Properties Choice of Ceramic Grade for Workpiece

Density Hardness Toughness Thermal Conductivity Machining Speed (V) Feed (f) Depth (DOC)

Grade Composition Color Application Grade Workpiece

(g/cm ) (HV) (MPa·m ) (cal/cm. sec. ℃) Type (m/min) (mm/rev) (mm)

3

1/2

SW400 Al2O3+SiC Green 3.8 2,100 7.0 - Gray Cast Iron (FC) Rough 150 ~ 800 0.2 ~ 0.5 3 ~ 6

SW800 Al2O3+SiC Green 3.7 2,100 7.0 - Gray Malleable (FCMB) Finish 200 ~ 1,200 0.3 ~ 0.5 0.1 ~ 0.5

ST100 Al2O3+TiC Black 4.20 2,100 4.00 0.08 ST100 Cast

ST300 Al2O3+TiCN Black 4.40 2,150 4.50 0.08 ST300 Iron Chilled Cast Iron Rough 30 ~ 100 0.1 ~ 0.2 0.5 ~ 1.5

ST500 Al2O3+TiCN Black 4.30 2,200 4.50 0.08 ST500 Finish 50 ~ 200 0.05 ~ 0.15 0.1 ~ 0.5

ST900 Al2O3+TiCN Black 4.30 2,250 4.70 0.08 ST900 Carbon Steel

TC100 Rough 150 ~ 400 0.2 ~ 0.5 2 ~ 5

TC100 ST100+TiN PVD Gold 4.20 2,150 4.00 - TC300 Alloy Steel Finish 200 ~ 800 0.05 ~ 0.2 0.1 ~ 0.5

TC300 ST300+TiN PVD Gold 4.40 2,200 4.50 - Steel Bearing Steel

TM300

TM300 ST300+AlTiN PVD Black 4.40 2,250 4.50 Rough 20 ~ 100 0.1 ~ 0.2 0.5 ~ 1.5

SD200 TiC+Al2O3 Black 4.60 2,200 4.50 0.07 Hard Steel (HRC 45≥) Finish 40 ~ 200 0.05 ~ 0.5 0.1 ~ 0.5

SZ200 Al2O3+ZrO2 White 4.00 1,800 4.50 0.07

SZ300 Al2O3+ZrO2 Pink 4.10 1,850 4.50 0.07 SD200 Ductile Cast Iron Rough 100 ~ 400 0.1 ~ 0.2 1 ~ 2

SN26 Si3N4 Black 3.30 1,600 5.00 0.06 Nodular Cast Iron Finish 200 ~ 800 0.05 ~ 0.25 0.1 ~ 0.5

SN300 Si3N4 Gray 3.20 1,600 6.00 0.05 Turning SZ200 Gray Cast Iron (FC) Rough 200 ~ 700 0.2 ~ 0.4 2 ~ 5

SN400 Si3N4 Gray 3.20 1,650 6.00 0.05 SZ300 Steel (HRC 45≤) Finish 300 ~ 1,200 0.05 ~ 0.3 0.1 ~ 0.5

SN500 Si3N4 Gray 3.20 1,700 6.00 0.05 SN26 Gray Cast Iron (FC) Rough 150 ~ 1,100 0.3 ~ 0.8 < 5

SN600 Si3N4 Black 3.20 1,700 6.50 0.07 SN300 Malleable (FCMB) Finish 250 ~ 1,200 0.15 ~ 0.4 < 1

SN800 Si3N4 Black 3.20 1,900 6.00 0.04 SN400 Gray

SN1000 Si3N4+Al2O3 Black 3.3 1,800 7.00 SN500 Cast Rough 20 ~ 100 1.0 ~ 2.0 < 5

SN400+PVD SN600 Iron Chilled Cast Iron

NC400 Gold 3.2 1,650 6.00 Finish 60 ~ 200 0.5 ~ 1.0 < 1

(AlTiN/TiN) NC400

Ni-Based Alloy

SN800 Rough 150 ~ 250 0.2 ~ 0.4 < 5

Choice of Ceramic Grade for Workpiece SN1000 Non-Ferrous Metal Finish 150 ~ 450 0.1 ~ 0.2 < 1

Inconel

ST100/ST300 SN26

ST500/ST900 SZ200 SN300/SN400 SN800 SW400 High temperature alloys Rough 180 ~ 360 0.1 ~ 0.25 1 ~ 3

TC100/TC300 SD200 SZ300 SN500/SN600 SN1000 SW400 SW800 SW800 Inconel Finish 180 ~ 450 0.1 ~ 0.30 0.5 ~ 2.0

TM300 NC400 Stellite

Gray Cast Iron ◎ ○ ◎ ◎ ○ SN26 Rough 100 ~ 1,200 0.3 ~ 0.5 < 5

Cast SN300 Gray Cast Iron (FC) Finish 150 ~ 1,500 0.3 ~ 0.7 < 3

Iron Chilled Cast Iron ◎ ◎ ◎ ◎

Ductile Cast Iron ○ ◎ ○ ○ ○ SN400

Mild Steel ○ SN500 Ductile Cast Iron Rough 90 ~ 500 0.1 ~ 0.3 < 5

SN600

Carbon Steel ○ Alloy Steel Finish 100 ~ 700 0.1 ~ 0.4 < 3

NC400

Alloy Steel ◎ ○ ◎ ○ ○ Milling

Forged Steel ◎ High temperature alloys

Heat Treated Steel ◎ SN800 Inconel Finish 700 ~ 1,000 0.05 ~ 0.15 / tooth 0.5 ~ 2.5

Steel High Speed Steel ◎ ◎ SN1000 Stellite

High Manganese Steel ○ ○ ○ ◎ ○ SW400 High temperature alloys

Stainless Steel SW800 Inconel Rough 150 ~ 400 0.05 ~ 0.1 / tooth 1 ~ 3

Heat Resistant Steel ○ ○ ○ ○ ○

Super Alloy Steel ○ ○ ◎ ○ ◎

Inconel ◎ ○ ◎

◎ : Excellent ○ : Good

8 union Materials cutting tools 9