Page 6 - UNION

P. 6

part. GRADE INFORMATION part.

A CErAMIC A

Union Ceramics take pride in its outstanding wear resistance and thermal shock resistance with high

turning speed cutting. Pure raw materials give stability and fine microstructure to the products. turning

& Through HIP process, shaped bodies are completely condensed so that the finished goods are strong &

Milling and resistant against fracture and wear. Milling

• Improved work efficiency by increasing cutting speed on extremely higher than carbide inserts.

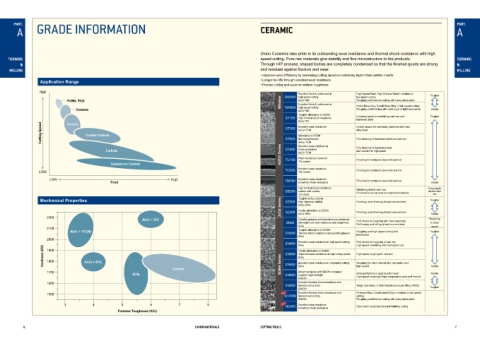

Application Range • Longer tool life through excellent wear resistance

• Precise cutting and superior surface roughness

High

Excellent flank & notch wear in High Speed Steel, High Chrome Steel in medium or Tougher

low speed cutting

SW400 high speed cutting

Whisker Excellent flank & notch wear in

PCBN, PCD Al2O3+SiC Roughing and medium cutting with heavy interruption

Ceramic SW800 high speed cutting Nickel Base Alloy, Cobalt Base Alloy in high speed cutting Harder

Roughing and finishing with continuous or light interruption

Al2O3+SiC

Tougher alternative to ST300

ST100 High thermal shock resistance Universal grade for machining cast iron and Tougher

Al2O3+TiC hardened steel

Cermet

Cutting Speed Coated Carbide ST300 Al2O3+TiCN alloy steel

Excellent wear resistance

A basic choice for machining hardened steel and

Alternative to PCBN

ST500

fine microstructure

Fine finishing for hardened steel and cast iron

Al2O3 Series Al2O3+TiCN

Excellent wear and thermal

shock resistance

Carbide ST900 Al2O3+TiCN Fine finishing for hardened steel

and cast iron in high speed

Wear resistance improved

Submicron Carbide TC100 TiN coated Finishing for hardened steel and cast iron

LOW TC300 Excellent wear resistance Finishing for hardened steel and cast iron

TiN coated

LOW High TM300 Excellent wear resistance

Feed & thermal shock resistance Finishing for hardened steel and cast iron Harder

High thermal shock resistance Finishing for

SD200 Usable with coolant Machining ductile cast iron ductile cast

Finishing for ductile cast iron and hard materials

TiC+Al2O3 iron

ZrO2 Series SZ300 Al2O3+ZrO2

Mechanical Properties SZ200 Toughened by zirconia Finishing, semi-finishing of cast iron and steel Tougher

High chemical stability

Harder alternative to SZ200

2200 Al2O3+ZrO2 Finishing, semi-finishing of cast iron and steel Harder

Al2O3 + SiC Good toughness and thermal shock resistance Roughing

SN26 Well balanced wear resistance and toughness First choice for roughing with interrupted cuts in lower

Roll turning and milling of cast iron and steel

Si3N4 speed

2100

Al2O3 + TiC(N) SN300 Tougher alternative to SN400 Roughing and high speed cutting with Tougher

Thermal shock resistance and good toughness

Si3N4 interruption

2000

SN400 Excellent wear resistance in high speed cutting First choice for roughing of cast iron

High speed machining with interrupted cuts

Si3N4

Hardness (HV) 1900 Al2O3 + ZrO2 SN500 Harder alternative to SN400 High speed roughing for cast iron

Improved wear resistance at high cutting speed

Si3N4

1800

high speed

Si3N4

Cermet Si3N4 Series SN600 Excellent wear resistance in interrupted cutting Roughing for hard material with interruption and Harder

1700 Advanced grade with SiAlON contained Great performance against notch wear Harder

Si3N4 SN800 superior edge strength

SiAlON High speed roughing of high temperature alloy and inconel

1600 Excellent thermal shock resistance and

SN900 thermal conductivity Tough machining in Heat Resistance Super Alloy (HRSA)

SiAlON Tougher

1500 Excellent thermal shock resistance and Ni-based Alloy, Cobalt-based Alloy in medium or low speed

SN1000 thermal conductivity cutting

SiAlON Roughing and Medium cutting with heavy interruption

3 4 5 6 7 8 NC400 Excellent wear resistance Cast Iron in roughing and semi-finishing cutting

Fracture Toughness (KIC) & thermal shock resistance

6 union Materials cutting tools 7