Page 12 - UNION

P. 12

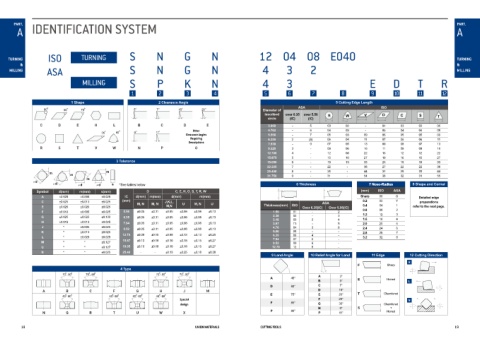

part. IDENTIFICATION SYSTEM part.

A A

ISO TURNING S N G N 12 04 08 E040

turning turning

& &

Milling ASA S N G N 4 3 2 Milling

MILLING S P K N 4 3 E D T R

1 2 3 4 5 6 7 8 9 10 11 12

1 Shape 2 Clearance Angle 5 Cutting Edge Length

ASA ISO

Diameter of

inscribed over 6.35 over 5.56

circle (IC) (IC)

C D E H L B C D E 3.969 - 5 03 02 - 04 03 03 06

Other 4.762 - 6 04 03 - 05 04 04 08

Clearance Angles 5.556 - 7 05 03 09 06 05 05 09

requiring 6.350 2 (8) 06 04 11 07 06 06 11

Descriptions 7.938 - 0 07 05 13 09 08 07 13

R S T V W N P O 9.525 3 - 09 06 16 11 09 09 16

12.700 4 - 12 08 22 15 12 12 22

15.875 5 - 15 10 27 19 16 15 27

3 Tolerance 19.050 6 - 19 13 33 23 19 19 33

22.225 7 - 22 - 38 27 22 22 38

25.400 8 - 25 - 44 31 25 25 44

31.750 0 - 31 - 54 38 32 31 55

*See tables below 6 Thickness 7 Nose-Radius 8 Shape and Corner

Symbol d(mm) m(mm) s(mm) D C, E, H, O, S, T, R, W (mm) ISO ASA

A ±0.025 ±0.005 ±0.025 IC d(mm) m(mm) d(mm) m(mm) Sharp 00 O Detailed edge

C ±0.025 ±0.013 ±0.025 (mm) M, N M, N J,K,L, U M, N U ASA 0.2 02 Y preparations

E ±0.025 ±0.025 ±0.025 M,N Thickness(mm) ISO Over 6.35(IC) Over 5.56(IC) 0.4 04 1 refer to the next page.

F ±0.013 ±0.005 ±0.025 5.56 ±0.05 ±0.11 ±0.05 ±0.08 ±0.08 ±0.13 1.59 01 - 2 0.8 08 2

G ±0.025 ±0.025 ±0.130 6.35 ±0.05 ±0.11 ±0.05 ±0.08 ±0.08 ±0.13 2.38 02 - 3 1.2 12 3 4

1.6

16

H ±0.013 ±0.013 ±0.025 7.94 ±0.05 ±0.11 ±0.05 ±0.08 ±0.08 ±0.13 3.18 03 2 - 4 5 2.0 20 5

T3

3.97

J * ±0.005 ±0.025 9.52 ±0.05 ±0.11 ±0.05 ±0.08 ±0.08 ±0.13 4.76 04 3 6 2.4 24 6

K * ±0.013 ±0.025 5.56 05 - - 2.8 28 7

L * ±0.025 ±0.025 12.70 ±0.08 ±0.15 ±0.08 ±0.13 ±0.13 ±0.20 6.35 06 4 5 - - 3.2 32 8

7.94

07

M * * ±0.127 15.87 ±0.10 ±0.18 ±0.10 ±0.18 ±0.15 ±0.27 9.52 09 6 -

U * * ±0.127 19.05 ±0.10 ±0.18 ±0.10 ±0.18 ±0.15 ±0.27 12.70 12 8 -

N * * ±0.025 25.40 - - ±0.13 ±0.25 ±0.18 ±0.38

9 Land Angle 10 Relief Angle for Land 11 Edge 12 Cutting Direction

r

F Sharp

4 Type

A 45° A 3° E

B 5° Honed L

D 60° C 7°

A B C F G H J M D 15°

E 75° E 20° T Chamfered

Special F 25° N

design F 85° G 30° Chamfered

N 0° S +

N Q R T U W X P 90° P 11° Honed

18 union Materials cutting tools 19