Page 13 - UNION

P. 13

part. IDENTIFICATION SYSTEM part.

A A

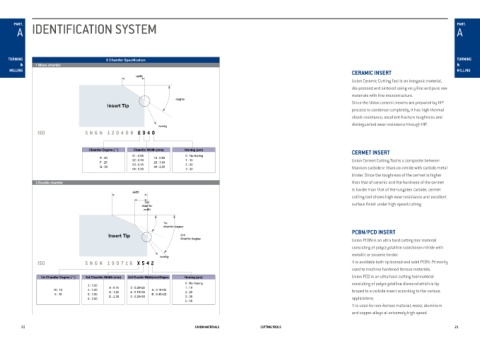

turning 8 Chamfer Specification turning

& 1 Mono chamfer &

Milling CErAMIC INSErT Milling

width

Union Ceramic Cutting Tool is an inorganic material,

die-pressed and sintered using very fine and pure raw

materials with fine microstructure.

degree

Insert Tip Since the Union ceramic inserts are prepared by HIP

process to condense completely, it has high thermal

shock resistance, excellent fracture toughness and

distinguished wear resistance through HIP.

honing

ISO SN G N 1 2 040 8 E040

Chamfer Degree ( ° ) Chamfer Width (mm) Honing (μm) CErMET INSErT

01 : 0.05 0 : No Honing

E : 20 10 : 0.50

F : 25 02 : 0.10 20 : 1.00 1 : 10 Union Cermet Cutting Tool is a composite between

G : 30 03 : 0.15 40 : 2.00 2 : 20 titanium carbide or titanium nitride with carbide-metal

04 : 0.20 3 : 30

binder. Since the toughness of the cermet is higher

2 Double chamfer than that of ceramic and the hardness of the cermet

is harder than that of the tungsten carbide, cermet

width

cutting tool shows high wear resistance and excellent

2nd surface finish under high speed cutting.

chamfer

width

1st

chamfer degree

PCBN/PCD INSErT

Insert Tip 2nd

chamfer degree Union PCBN is an ultra hard cutting tool material

consisting of polycrystalline cubicboron nitride with

metallic or ceramic binder.

honing

ISO SN G N 1 90 7 1 6 X 5 42 It is available both tip brazed and solid PCBN. Primarily

used to machine hardened ferrous materials.

1st Chamfer Degree ( ° ) 1st Chamfer Width (mm) 2nd Chamfer Width(mm)×Degree Honing (μm) Union PCD is an ultra hard cutting tool material

0 : No Honing consisting of polycrystalline diamond which is tip

3 : 1.00 A : 0.75 3 : 0.20×25 1 : 10

W : 10 4 : 1.20 B : 1.25 4 : 0.10×30 A : 0.15×30 2 : 20 brazed to a carbide insert according to the various

X : 15 5 : 1.50 D : 2.30 5 : 0.20×30 B : 0.45×25 3 : 30

6 : 2.00 applications.

5 : 50

It is used for non-ferrous material, wood, aluminum

and copper alloys at extremely high speed.

20 union Materials cutting tools 21