Page 184 - UNION

P. 184

part. Technical DaTa RECOMMENDATION OF CUTTING CONDITIONS Technical DaTa RECOMMENDATION OF CUTTING CONDITIONS part.

B B

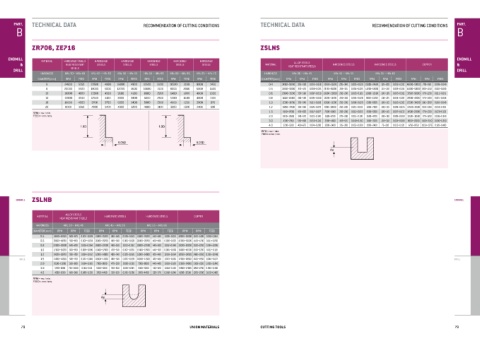

Zr706, Ze716 ZSlnS

endmill MATERIAL HARDENED STEELS HARDENED HARDENED HARDENED HARDENED HARDENED endmill

ALLOY STEELS

& HEAT RESISTANT STEELS STEELS STEELS STEELS STEELS MATERIAL HEAT RESISTANT STEELS HARDENED STEELS HARDENED STEELS COPPER &

drill STEELS drill

HARDNESS HRc 30 ~ HRc 40 HRc 40 ~ HRc 50 HRc 50 ~ HRc 55 HRc 55 ~ HRc 60 HRc 60 ~ HRc 65 HRc 65 ~ HRc 70 HARDNESS HRc 30 ~ HRc 45 HRc 45 ~ HRc 55 HRc 55 ~ HRc 65

DIAMETER(mm) RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED DIAMETER(mm) RPM RPM FEED RPM RPM FEED RPM RPM FEED RPM RPM FEED

6 24800 5350 23500 4900 16000 4900 13500 3300 10500 2100 8000 1450 0.4 34100~50000 350~590 0.005~0.028 30500~35200 295~340 0.003~0.020 18300~24600 120~200 0.002~0.012 48000~50000 790~920 0.008~0.048

8 20000 5500 19000 5000 12000 4600 10000 3100 8000 2000 6000 1400 0.5 25650~33000 370~470 0.006~0.035 23750~26000 285~315 0.004~0.025 14200~18000 115~130 0.003~0.015 44000~50000 800~1150 0.010~0.060

10 16000 4900 15500 4500 9500 4100 8000 2900 6400 1800 4800 1300 0.6 20900~35200 330~560 0.007~0.030 19900~22000 260~290 0.005~0.021 11900~15500 100~120 0.003~0.013 37500~50000 770~1250 0.011~0.051

12 13000 4500 12500 4100 8000 3800 6600 2500 5300 1600 4000 1150 0.8 16150~26400 360~590 0.009~0.040 15200~16700 280~310 0.006~0.028 9000~11700 110~125 0.004~0.017 28500~47000 770~1300 0.015~0.068

16 10000 4000 9700 3700 6000 3400 5000 2300 4000 1250 3000 870 1.0 12300~18700 350~540 0.011~0.028 10500~11500 250~280 0.008~0.020 6300~8050 100~115 0.005~0.012 22500~34000 810~1300 0.018~0.048

20 8000 3350 7800 3400 4800 3200 4000 2100 3200 1020 2400 690 1.2 10450~17600 350~590 0.025~0.070 9100~10000 250~280 0.015~0.042 5400~7000 100~115 0.009~0.026 22500~31500 950~1350 0.036~0.101

1.5 9100~17600 430~830 0.017~0.077 7000~8000 250~280 0.012~0.055 4300~5500 100~115 0.007~0.033 14500~25000 770~1320 0.028~0.132

RPM = rev. / min.

FEED = mm / min. 2.0 6350~10550 340~570 0.021~0.140 6100~6700 270~300 0.015~0.100 3600~4700 100~120 0.009~0.060 11500~18500 770~1250 0.036~0.240

3.0 4300~7050 550~900 0.056~0.210 3990~4600 445~515 0.040~0.150 2400~3200 105~310 0.024~0.090 9000~13000 1400~2110 0.096~0.360

1.0D 1.0D 4.0 3200~5300 400~675 0.074~0.280 3000~3400 335~380 0.053~0.200 1800~2400 75~230 0.032~0.120 6750~9750 1050~1575 0.128~0.480

RPM = rev. / min.

FEED = mm / min.

0.05D 0.03D

Ae

ZSlnb

endmill endmill

ALLOY STEELS

MATERIAL HARDENED STEELS HARDENED STEELS COPPER

HEAT RESISTANT STEELS

HARDNESS HRc 30 ~ HRc 45 HRc 45 ~ HRc 55 HRc 55 ~ HRc 65

DIAMETER(mm) RPM RPM FEED RPM RPM FEED RPM RPM FEED RPM RPM FEED

0.5 34100~49500 600~870 0.007~0.028 31900~35200 490~540 0.005~0.023 31900~35200 440~480 0.005~0.021 49000~50000 1100~1400 0.010~0.042

0.6 28600~40700 590~850 0.007~0.034 26400~29700 480~540 0.006~0.028 26400~29700 400~480 0.006~0.025 42000~50000 1100~1700 0.011~0.050

0.8 22000~30800 640~890 0.016~0.064 19800~22000 490~550 0.013~0.052 19800~22000 440~500 0.012~0.048 31000~50000 1100~2250 0.024~0.096

1.0 17600~24200 600~850 0.008~0.080 15400~17600 470~540 0.007~0.065 15400~17600 440~500 0.006~0.060 24000~49500 1100~2200 0.012~0.120

1.2 14300~18700 590~780 0.024~0.032 12000~14000 480~540 0.020~0.026 12000~14000 420~480 0.018~0.024 28500~38500 1480~1950 0.036~0.048

drill 1.5 11000~14300 580~760 0.031~0.048 10000~11500 480~540 0.025~0.039 10000~11500 420~480 0.023~0.036 17000~28500 1100~1950 0.046~0.072 drill

2.0 8500~11000 590~800 0.024~0.160 7900~8800 470~530 0.020~0.130 7900~8800 440~480 0.018~0.120 12600~24000 1100~2150 0.036~0.240

3.0 5700~8200 730~1000 0.064~0.24 5300~5800 590~650 0.052~0.195 5300~5800 550~620 0.048~0.120 11900~17000 1850~2700 0.096~0.360

4.0 4300~6200 680~990 0.080~0.320 3950~4400 550~620 0.065~0.260 3850~4400 530~570 0.060~0.240 6600~12500 1260~2500 0.120~0.480

RPM = rev. / min.

FEED = mm / min.

Ae

78 Union Materials cUttinG tools 79