Page 180 - UNION

P. 180

part. Technical DaTa Technical DaTa part.

B B

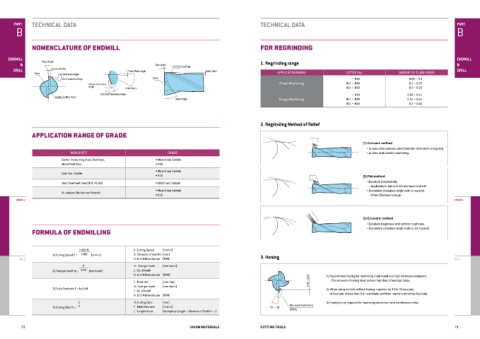

nomenclature oF endmill For regrinding

endmill endmill

& 1. Regrinding range &

drill drill

APPLICATION RANGE CUTTER Dia. AMOUNT OF FLANK WEAR

~ Ø10 0.05 ~ 0.1

Finish Machining Ø11 ~ Ø30 0.1 ~ 0.25

Ø31 ~ Ø50 0.2 ~ 0.35

~ Ø10 0.08 ~ 0.15

Rough Machining Ø11 ~ Ø30 0.15 ~ 0.35

Ø31 ~ Ø50 0.3 ~ 0.45

2. Regrinding Method of Relief

application range oF grade

(1) Concave method

• In case when precise outer Diameter dimension is required.

WORKPIECE GRADE • In case of aluminium machining.

Carbon Steel, Alloy Steel, Tool Steel, • Micro Grain Carbide

Metal Mold Steel • P30

• Micro Grain Carbide

Cast Iron, Ductile

• K10 (2) Flat method

Heat Treatment Steel(HRC 40-60) • Ultrafinest Carbide • Excellent machinability

- Applicable to ball end mill and taper end mill.

• Micro Grain Carbide • Secondary clearance angle work is required.

Aluminium, Nonferrous Meterial

• K10 - When Diameter is large.

endmill endmill

(3) Eccentric method

• Excellent toughness and surface roughness.

• Secondary clearance angle work is not required.

Formula oF endmilling

π×D×N V : Cutting Speed (m/min)

1) Cutting Speed V = 1000 (m/min) D : Diameter of End Mill (mm) 3. honing

drill N : End Mill revolution (RPM) drill

F fz : Feed per tooth (mm/tooth)

2) Feed per tooth fz = Z×N (mm/tooth) Z : No. of teeth

N : End Mill revolution (RPM) 1) Recommend honing for machining mold metal and high hardness workpiece.

F : Feed rate (mm/min) - The amount of honing shall be less than that of feed per blade.

fz : Feed per tooth (mm/tooth)

3) Table Feed rate F = fz×Z×N 2) Whan using end mill without honing, machine for 10 to 30 seconds

Z : No. of teeth

N : End Mill revolution (RPM) at feed rate of less than 0.01 mm/blade and then machine at normal feed rate.

L Tc: Cutting Time (min) 3) Honing is not required for machining aluminium and non-ferrous metal.

4) Cutting Time Tc = F F : Table feed rate (m/min)

L : Length of cut (workpiece Length + Diameter of Endmill + α)

70 Union Materials cUttinG tools 71