Page 87 - Iscar

P. 87

SELECTION GUIDE

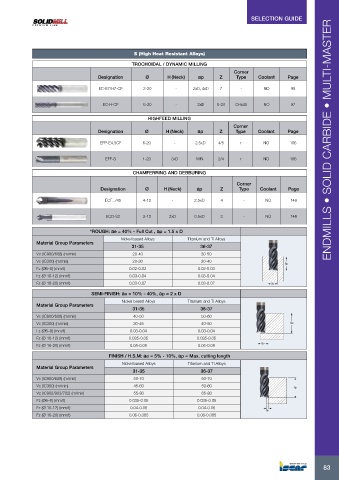

S (High Heat Resistant Alloys)

TROCHOIDAL / DYNAMIC MILLING

Corner

Designation Ø H (Neck) ap Z Type Coolant Page

EC-E7/H7-CF 2-20 - 2xD, 4xD 7 - NO 95

EC-H-CF 6-20 - 2xD 6-20 CHx45 NO 97

HIGHFEED MILLING

Corner

Designation Ø H (Neck) ap Z Type Coolant Page

EFP-E4,5CF 6-20 - 2.5xD 4/5 r NO 106 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EFF-S 1-20 3xD MIN. 2/4 r NO 106

CHAMFERRING AND DEBBURING

Corner

Designation Ø H (Neck) ap Z Type Coolant Page

ECF.../45 4-12 - 2.5xD 4 - NO 146

ECD-S2 3-12 2xD 0.5xD 2 - NO 146

*ROUGH: ae = 40% - Full Cut , ap = 1.5 x D

Nickel based Alloys Titanium and Ti Alloys

Material Group Parameters

31-35 36-37

Vc (IC900/608) (m/min) 20-40 30-50

Vc (IC300) (m/min) 20-30 20-40

ap

Fz (Ø6–8) (mm/t) 0.02-0.03 0.02-0.03

Fz (Ø 10-12) (mm/t) 0.03-0.04 0.03-0.04

Fz (Ø 16-20) (mm/t) 0.03-0.07 0.03-0.07 ae

SEMI-FINISH: ae = 10% - 40%, ap = 2 x D

Nickel based Alloys Titanium and Ti Alloys

Material Group Parameters

31-35 36-37

Vc (IC900/608) (m/min) 40-50 50-60

Vc (IC300) (m/min) 30-45 40-50 ap

Fz (Ø6–8) (mm/t) 0.03-0.04 0.03-0.04

Fz (Ø 10-12) (mm/t) 0.035-0.05 0.035-0.05

Fz (Ø 16-20) (mm/t) 0.05-0.08 0.05-0.08 ae

FINISH / H.S.M: ae = 5% - 10%, ap = Max. cutting length

Nickel based Alloys Titanium and Ti Alloys

Material Group Parameters

31-35 36-37

Vc (IC900/608) (m/min) 50-70 60-70

Vc (IC300) (m/min) 45-60 50-60 ap

Vc (IC902/903/702) (m/min) 55-80 65-80

Fz (Ø6–8) (mm/t) 0.035-0.05 0.035-0.05

Fz (Ø 10-12) (mm/t) 0.04-0.06 0.04-0.06

ae

Fz (Ø 16-20) (mm/t) 0.06-0.085 0.06-0.085

83

83