Page 91 - Iscar

P. 91

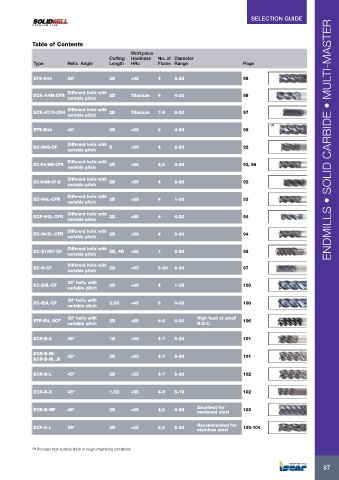

SELECTION GUIDE

Table of Contents

Workpiece

Cutting Hardness No. of Diameter

Type Helix Angle Length HRc Flutes Range Page

EFS-E44 38º 2D <45 4 6-25 98

Different helix with

ECK-H4M-CFR 2D Titanium 4 4-20 96

variable pitch

Different helix with

ECK-H7/9-CFR 2D Titanium 7-9 6-20 97

variable pitch

(1)

EFS-B44 45º 2D <55 4 4-25 99

Different helix with ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EC-H4S-CF D <55 4 6-20 92

variable pitch

Different helix with

EC-H4/5M-CFR 2D <55 4,5 4-25 93, 95

variable pitch

Different helix with

EC-H4M-CF-E 2D <55 4 6-20 92

variable pitch

Different helix with

EC-H4L-CFR 2D <55 4 1-20 93

variable pitch

Different helix with

ECP-H4L-CFR 2D <55 4 6-20 94

variable pitch

Different helix with

EC-H4XL-CFR 2D <55 4 6-20 94

variable pitch

Different helix with

EC-E7/H7-CF 2D, 4D <55 7 2-20 95

variable pitch

Different helix with

EC-H-CF 2D <55 6-20 6-20 97

variable pitch

38º helix with

EC-E4L-CF 2D <45 4 1-25 100

variable pitch

38º helix with

EC-E5L-CF 2.5D <45 5 6-20 100

variable pitch

38º helix with High feed at small

EFP-E4, 5CF 2D <55 4-5 6-20 106

variable pitch D.O.C.

ECR-B-S 45º 1D <55 4-7 5-20 101

ECR-B-M/ 45º 2D <55 4-7 5-20 101

ECR-B-M...R

ECR-B-L 45º 2D <55 4-7 6-20 102

ECR-B-X 45º 1.5D <55 4-5 8-16 102

Excellent for

ECR-B-MF 45º 2D <65 4,6 6-25 103

hardened steel

Recommended for

ECP-E-L 38º 2D <45 3,4 5-20 103-104

stainless steel

(1) Provides high surface finish in rough machining conditions

87

87