Page 85 - Iscar

P. 85

SELECTION GUIDE

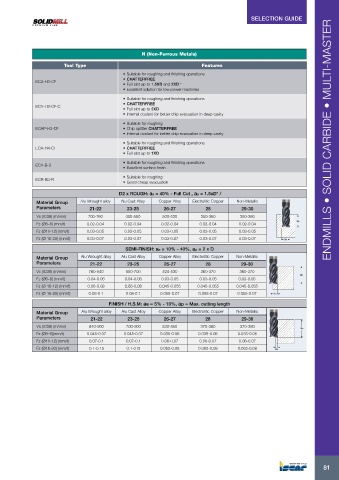

N (Non-Ferrous Metals)

Tool Type Features

• Suitable for roughing and finishing operations

• CHATTERFREE

ECA-H3-CF

• Full slot up to 1.5XD and 2XD *

• Excellent solution for low power machines

• Suitable for roughing and finishing operations

• CHATTERFREE

ECA-H3-CF-C

• Full slot up to 2XD

• Internal coolant for better chip evacuation in deep cavity

• Suitable for roughing

ECAP-H3-CF • Chip splitter CHATTERFREE

• Internal coolant for better chip evacuation in deep cavity

• Suitable for roughing and finishing operations ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ECA-H4-CF • CHATTERFREE

• Full slot up to 1XD

• Suitable for roughing and finishing operations

ECA-B-3

• Excellent surface finish

• Suitable for roughing

ECR-B3-R

• Good cheap evacuation

D2 x ROUGH: ae = 40% - Full Cut , ap = 1.5xD* /

Material Group Alu Wrought alloy Alu Cast Alloy Copper Alloy Electrolitic Copper Non-Metallic

Parameters 21-22 23-25 26-27 28 29-30

Vc (IC08) (m/min) 700-760 400-550 500-520 350-360 350-360

ap

Fz (Ø6–8) (mm/t) 0.02-0.04 0.02-0.04 0.02-0.04 0.02-0.04 0.02-0.04

Fz (Ø10-12) (mm/t) 0.03-0.05 0.03-0.05 0.03-0.05 0.03-0.05 0.03-0.05

Fz (Ø 16-20) (mm/t) 0.03-0.07 0.03-0.07 0.03-0.07 0.03-0.07 0.03-0.07 ae

SEMI-FINISH: ae = 10% - 40%, ap = 2 x D

Material Group Alu Wrought alloy Alu Cast Alloy Copper Alloy Electrolitic Copper Non-Metallic

Parameters 21-22 23-25 26-27 28 29-30

Vc (IC08) (m/min) 760-840 550-700 520-530 360-370 360-370

ap

Fz (Ø6–8) (mm/t) 0.04-0.06 0.04-0.06 0.03-0.05 0.03-0.05 0.03-0.05

Fz (Ø 10-12) (mm/t) 0.06-0.08 0.06-0.08 0.045-0.055 0.045-0.055 0.045-0.055

Fz (Ø 16-20) (mm/t) 0.08-0.1 0.08-0.1 0.055-0.07 0.055-0.07 0.055-0.07 ae

FINISH / H.S.M: ae = 5% - 10%, ap = Max. cutting length

Material Group Alu Wrought alloy Alu Cast Alloy Copper Alloy Electrolitic Copper Non-Metallic

Parameters 21-22 23-25 26-27 28 29-30

Vc (IC08) (m/min) 840-900 700-900 530-550 370-380 370-380 ap

Fz (Ø6–8)(mm/t) 0.045-0.07 0.045-0.07 0.035-0.06 0.035-0.06 0.035-0.06

Fz (Ø10-12) (mm/t) 0.07-0.1 0.07-0.1 0.06-0.07 0.06-0.07 0.06-0.07

Fz (Ø16-20) (mm/t) 0.1-0.15 0.1-015 0.065-0.08 0.065-0.08 0.065-0.08 ae

81

81