Page 83 - Iscar

P. 83

SELECTION GUIDE

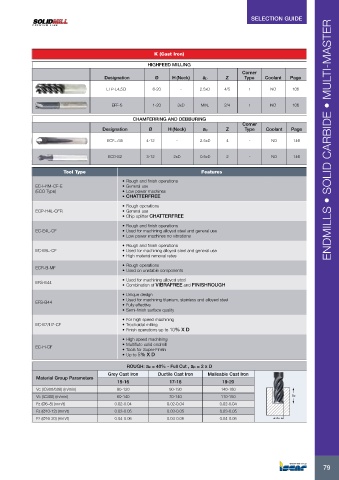

K (Cast Iron)

HIGHFEED MILLING

Corner

Designation Ø H (Neck) ap Z Type Coolant Page

EFP-E4,5CF 6-20 - 2.5xD 4/5 r NO 106

EFF-S 1-20 3xD MIN. 2/4 r NO 106

CHAMFERRING AND DEBBURING

Corner

Designation Ø H (Neck) ap Z Type Coolant Page

ECF.../45 4-12 - 2.5xD 4 - NO 146 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ECD-S2 3-12 2xD 0.5xD 2 - NO 146

Tool Type Features

• Rough and finish operations

EC-H4M-CF-E • General use

(ECO Type) • Low power machines

• CHATTERFREE

• Rough operations

ECP-H4L-CFR • General use

• Chip splitter CHATTERFREE

• Rough and finish operations

EC-E4L-CF • Used for machining alloyed steel and general use

• Low power machines no vibrations

• Rough and finish operations

EC-E5L-CF • Used for machining alloyed steel and general use

• High material removal rates

• Rough operations

ECR-B-MF

• Used on unstable components

• Used for machining alloyed steel

EFS-E44 • Combination of VIBRAFREE and FINISHROUGH

• Unique design

• Used for machining titanium, stainless and alloyed steel

EFS-B44

• Fully effective

• Semi-finish surface quality

• For high speed machining

EC-E7/H7-CF • Trochoidal milling

• Finish operations up to 10% X D

• High speed machining

• Multiflute solid endmill

EC-H-CF

• Tools for Super-Finish

• Up to 5% X D

ROUGH: ae = 40% - Full Cut , ap = 2 x D

Grey Cast Iron Ductile Cast Iron Malleable Cast Iron

Material Group Parameters

15-16 17-18 19-20

Vc (IC900/608) (m/min) 80-130 90-130 140-180

Vc (IC300) (m/min) 60-140 70-140 110-150 ap

Fz (Ø6–8) (mm/t) 0.02-0.04 0.02-0.04 0.02-0.04

Fz (Ø10-12) (mm/t) 0.03-0.05 0.03-0.05 0.03-0.05

Fz (Ø16-20) (mm/t) 0.04-0.06 0.04-0.06 0.04-0.06 ae

79

79