Page 78 - Iscar

P. 78

SELECTION GUIDE

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

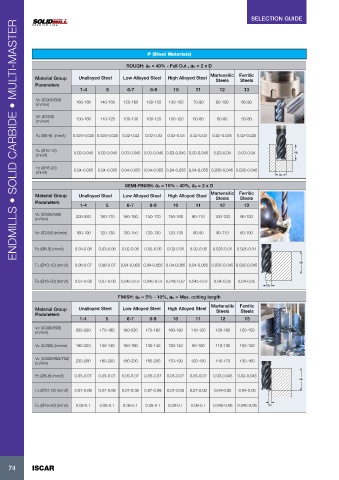

P (Steel Materials)

ROUGH: ae = 40% - Full Cut , ap = 2 x D

Martensitic Ferritic

Material Group Unalloyed Steel Low Alloyed Steel High Alloyed Steel Steels Steels

Parameters

1-4 5 6-7 8-9 10 11 12 13

Vc (IC900/608 160-180 140-150 120-160 130-150 130-150 70-90 80-100 60-90

(m/min)

Vc (IC300) 130-160 110-120 100-130 100-120 100-120 60-80 60-90 50-80

(m/min)

Fz (Ø6-8) (mm/t) 0.025-0.035 0.025-0.035 0.02-0.03 0.02-0.03 0.02-0.03 0.02-0.03 0.02-0.035 0.02-0.035

Fz (Ø10-12) 0.03-0.045 0.03-0.045 0.03-0.045 0.03-0.045 0.03-0.045 0.03-0.045 0.03-0.04 0.03-0.04 ap

(mm/t)

Fz (Ø16-20) 0.04-0.055 0.04-0.055 0.04-0.055 0.04-0.055 0.04-0.055 0.04-0.055 0.035-0.045 0.035-0.045

(mm/t)

ae

SEMI-FINISH: ae = 10% - 40%, ap = 2 x D

Material Group Unalloyed Steel Low Alloyed Steel High Alloyed Steel Martensitic Ferritic

Steels

Steels

Parameters

1-4 5 6-7 8-9 10 11 12 13

Vc (IC900/608) 200-220 150-170 160-180 150-170 150-160 90-110 100-130 90-120

(m/min)

Vc (IC300) (m/min) 160-190 120-130 130-150 120-130 120-130 80-90 90-110 80-100

Fz (Ø6-8) (mm/t) 0.03-0.06 0.03-0.06 0.02-0.05 0.02-0.05 0.02-0.05 0.02-0.05 0.025-0.04 0.025-0.04

ap

Fz (Ø10-12) (mm/t) 0.06-0.07 0.06-0.07 0.04-0.065 0.04-0.065 0.04-0.065 0.04-0.065 0.035-0.045 0.035-0.045

Fz (Ø16-20) (mm/t) 0.07-0.08 0.07-0.08 0.045-0.07 0.045-0.07 0.045-0.07 0.045-0.07 0.04-0.05 0.04-0.05

ae

FINISH: ae = 5% - 10%, ap = Max. cutting length

Martensitic Ferritic

Material Group Unalloyed Steel Low Alloyed Steel High Alloyed Steel Steels Steels

Parameters

1-4 5 6-7 8-9 10 11 12 13

Vc (IC900/608) 220-280 170-180 180-220 170-180 160-180 110-120 130-160 120-150

(m/min)

Vc (IC300) (m/min) 190-220 130-140 150-180 130-140 130-140 90-100 110-130 100-120

Vc (IC902/903/702) 230-290 180-200 190-230 180-230 170-190 120-130 140-170 130-160

(m/min)

Fz (Ø6-8) (mm/t) 0.05-0.07 0.05-0.07 0.05-0.07 0.05-0.07 0.05-0.07 0.05-0.07 0.03-0.045 0.03-0.045

ap

Fz (Ø10-12) (mm/t) 0.07-0.08 0.07-0.08 0.07-0.08 0.07-0.08 0.07-0.08 0.07-0.08 0.04-0.05 0.04-0.05

Fz (Ø16-20) (mm/t) 0.08-0.1 0.08-0.1 0.08-0.1 0.08-0.1 0.08-0.1 0.08-0.1 0.045-0.06 0.045-0.06 ae

ISCAR

74 ISCAR

74