Page 84 - Iscar

P. 84

SELECTION GUIDE

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

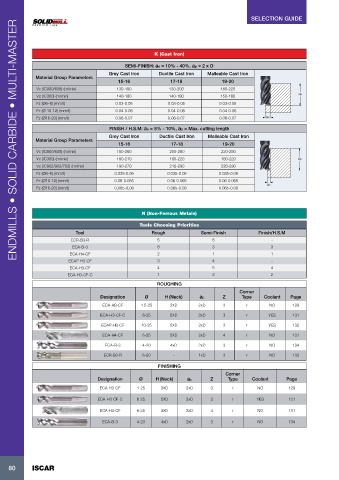

K (Cast Iron)

SEMI-FINISH: ae = 10% - 40%, ap = 2 x D

Grey Cast Iron Ductile Cast Iron Malleable Cast Iron

Material Group Parameters

15-16 17-18 19-20

Vc (IC900/608) (m/min) 130-180 130-200 180-220

Vc (IC300) (m/min) 140-180 140-180 150-180 ap

Fz (Ø6–8) (mm/t) 0.03-0.05 0.03-0.05 0.03-0.05

Fz (Ø 10-12) (mm/t) 0.04-0.06 0.04-0.06 0.04-0.06

Fz (Ø16-20) (mm/t) 0.06-0.07 0.06-0.07 0.06-0.07 ae

FINISH / H.S.M: ae = 5% - 10%, ap = Max. cutting length

Grey Cast Iron Ductile Cast Iron Malleable Cast Iron

Material Group Parameters

15-16 17-18 19-20

Vc (IC900/608) (m/min) 180-260 200-280 220-280

Vc (IC300) (m/min) 180-210 180-220 180-220 ap

Vc (IC902/903/702) (m/min) 190-270 210-290 220-290

Fz (Ø6–8) (mm/t) 0.035-0.06 0.035-0.06 0.035-0.06

Fz (Ø10-12) (mm/t) 0.06-0.065 0.06-0.065 0.06-0.065

ae

Fz (Ø16-20) (mm/t) 0.065-0.08 0.065-0.08 0.065-0.08

N (Non-Ferrous Metals)

Tools Choosing Priorities

Tool Rough Semi-Finish Finish/H.S.M

ECR-B3-R 5 6 -

ECA-B-3 6 3 3

ECA-H4-CF 2 1 1

ECAP-H3-CF 3 4 -

ECA-H3-CF 4 5 4

ECA-H3-CF-C 1 2 2

ROUGHING

Corner

Designation Ø H (Neck) ap Z Type Coolant Page

ECA-H3-CF 1.5-25 3XD 2xD 3 r NO 129

ECA-H3-CF-C 6-25 5XD 2xD 3 r YES 131

ECAP-H3-CF 10-25 5XD 2xD 3 r YES 132

ECA-H4-CF 6-25 5XD 2xD 4 r NO 131

ECA-B-3 4-20 4xD 2xD 3 r NO 134

ECR-B3-R 6-20 - 1xD 3 r NO 133

FINISHING

Corner

Designation Ø H (Neck) ap Z Type Coolant Page

ECA-H3-CF 1-25 3XD 2xD 3 r NO 129

ECA-H3-CF-C 6-25 5XD 2xD 3 r YES 131

ECA-H4-CF 6-25 5XD 2xD 4 r NO 131

ECA-B-3 4-20 4xD 2xD 3 r NO 134

ISCAR

80 ISCAR

80