Page 845 - Iscar

P. 845

INTRODUCTION

INTRODUCTION

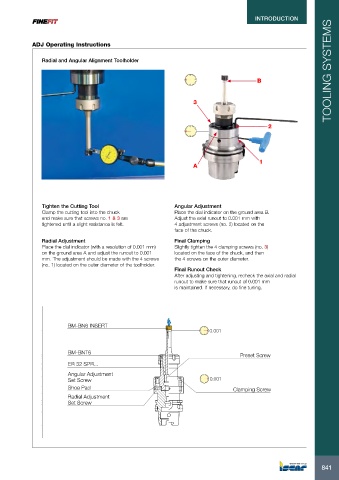

ADJ Operating Instructions

Radial and Angular Alignment Toolholder

B TOOLING SYSTEMS

3

2

1

A

Tighten the Cutting Tool Angular Adjustment

Clamp the cutting tool into the chuck Place the dial indicator on the ground area B.

and make sure that screws no. 1 & 3 are Adjust the axial runout to 0.001 mm with

tightened until a slight resistance is felt. 4 adjustment screws (no. 2) located on the

face of the chuck.

Radial Adjustment Final Clamping

Place the dial indicator (with a resolution of 0.001 mm) Slightly tighten the 4 clamping screws (no. 3)

on the ground area A and adjust the runout to 0.001 located on the face of the chuck, and then

mm. The adjustment should be made with the 4 screws the 4 screws on the outer diameter.

(no. 1) located on the outer diameter of the toolholder.

Final Runout Check

After adjusting and tightening, recheck the axial and radial

runout to make sure that runout of 0.001 mm

is maintained. If necessary, do fine tuning.

BM-BN6 INSERT

0.001

BM-BNT6

Preset Screw

ER 32 SPR...

Angular Adjustment

Set Screw 0.001

Shoe Pad Clamping Screw

Radial Adjustment

Set Screw

841

841