Page 840 - Iscar

P. 840

INTRODUCTION

TOOLING SYSTEMS

Balanceable Collet Chucks

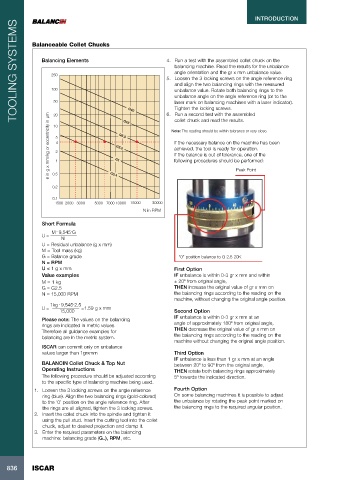

Balancing Elements 4. Run a test with the assembled collet chuck on the

balancing machine. Read the results for the unbalance

angle orientation and the gr x mm unbalance value.

250

5. Loosen the 3 locking screws on the angle reference ring

and align the two balancing rings with the measured

100 unbalance value. Rotate both balancing rings to the

unbalance angle on the angle reference ring (or to the

50 laser mark on balancing machines with a laser indicator).

Tighten the locking screws.

G40 6. Run a second test with the assembled

e in g x mm/kg or eccentricity in µm 5 4 2 1 G1 G6.3 Note: The reading should be within tolerance or very close.

20

collet chuck and read the results.

G16

10

If the necessary balance on the machine has been

achieved, the tool is ready for operation.

G2.5

If the balance is out of tolerance, one of the

following procedures should be performed:

0.5

0.2 G0.4 Peak Point

0.1

1500 2000 3000 5000 7000 10000 15000 30000

N in RPM

Short Formula

.

.

M 9,545 G

U =

N

U = Residual unbalance (g x mm)

M = Tool mass (kg)

G = Balance grade “0” position balance to G 2.5 20K

N = RPM

U < 1 g x mm First Option

Value examples IF unbalance is within 0-3 gr x mm and within

M = 1 kg ± 20º from original angle,

G = G2.5 THEN increase the original value of gr x mm on

N = 15,000 RPM the balancing rings according to the reading on the

machine, without changing the original angle position.

.

.

1kg 9,545 2.5

U = =1.59 g x mm

15,000 Second Option

Please note: The values on the balancing IF unbalance is within 0-3 gr x mm at an

rings are indicated in metric values. angle of approximately 180º from original angle,

Therefore all guidance examples for THEN decrease the original value of gr x mm on

balancing are in the metric system. the balancing rings according to the reading on the

machine without changing the original angle position.

ISCAR can commit only on unbalance

values larger than 1grxmm Third Option

IF unbalance is less than 1 gr x mm at an angle

BALANCIN Collet Chuck & Top Nut between 20º to 90º from the original angle,

Operating Instructions THEN rotate both balancing rings approximately

The following procedure should be adjusted according 5º towards the indicated direction.

to the specific type of balancing machine being used.

1. Loosen the 3 locking screws on the angle reference Fourth Option

ring (blue). Align the two balancing rings (gold-colored) On some balancing machines it is possible to adjust

to the ‘0’ position on the angle reference ring. After the unbalance by rotating the peak point marked on

the rings are all aligned, tighten the 3 locking screws. the balancing rings to the required angular position.

2. Insert the collet chuck into the spindle and tighten it

using the pull stud. Insert the cutting tool into the collet

chuck, adjust to desired projection and clamp it.

3. Enter the required parameters on the balancing

machine: balancing grade (G..), RPM, etc.

ISCAR

836 ISCAR

836