Page 842 - Iscar

P. 842

INTRODUCTION

INTRODUCTION

TOOLING SYSTEMS

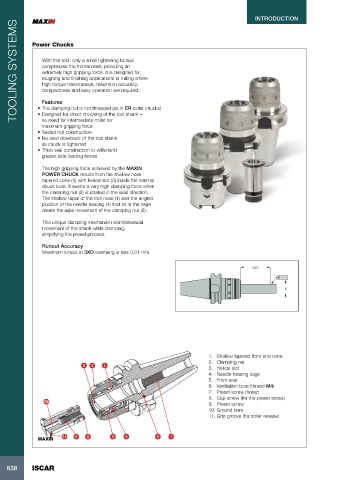

Power Chucks

With this tool, only a small tightening torque

compresses the frontal nose, providing an

extremely high gripping force. It is designed for

roughing and finishing applications in milling where

high torque transmission, maximum accuracy,

compactness and easy operation are required.

Features

• The clamping nut is not threaded (as in ER collet chucks)

• Designed for direct chucking of the tool shank –

no need for intermediate collet for

maximum gripping force

• Sealed nut construction

• No axial drawback of the tool shank

as chuck is tightened

• Thick wall construction to withstand

greater side loading forces

The high gripping force achieved by the MAXIN

POWER CHUCK results from the shallow nose

tapered cone (1) with helical slot (3) inside the internal

chuck bore. It exerts a very high clamping force when

the clamping nut (2) is rotated in the axial direction.

The shallow taper of the tool nose (1) and the angled

position of the needle bearing (4) that sit in the cage

create the axial movement of the clamping nut (2).

This unique clamping mechanism eliminatesaxial

movement of the shank while clamping,

simplifying the preset process.

Runout Accuracy

Maximum runout at 3XD overhang is less 0.01 mm

3xD

0.01

D

1. Shallow tapered front end cone

2. Clamping nut

3. Helical slot

4. Needle bearing cage

5. Front seal

6. Ventilation bore (thread M4)

7. Preset screw thread

8. Cap screw (for the preset screw)

9. Preset screw

10. Ground bore

11. Grip groove (for collet release)

MAXIN

ISCAR

838

838 ISCAR