Page 850 - Iscar

P. 850

INTRODUCTION

TOOLING SYSTEMS

Hydraulic Chucks

ISCAR-ETM has expanded its toolholder clamping

options by adding hydraulic chucks.

These hydraulic chucks range from 6-32 mm.

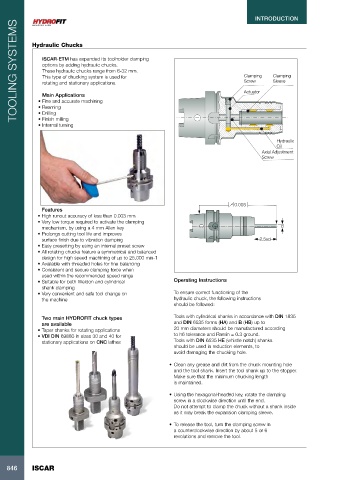

This type of chucking system is used for Clamping Clamping

rotating and stationary applications. Screw Sleeve

Actuator

Main Applications

• Fine and accurate machining

• Reaming

• Drilling

• Finish milling

• Internal turning

Hydraulic

Oil

Axial Adjustment

Screw

0.003

Features

• High runout accuracy of less than 0.003 mm

• Very low torque required to activate the clamping

mechanism, by using a 4 mm Allen key d

• Prolongs cutting tool life and improves

surface finish due to vibration damping 2.5xd

• Easy presetting by using an internal preset screw

• All rotating chucks feature a symmetrical and balanced

design for high speed machining of up to 25,000 min-1

• Available with threaded holes for fine balancing

• Consistent and secure clamping force when

used within the recommended speed range

• Suitable for both Weldon and cylindrical Operating Instructions

shank clamping

• Very convenient and safe tool change on To ensure correct functioning of the

the machine hydraulic chuck, the following instructions

should be followed:

Two main HYDROFIT chuck types Tools with cylindrical shanks in accordance with DIN 1835

are available and DIN 6535 forms (HA) and B (HB) up to

• Taper shanks for rotating applications 20 mm diameters should be manufactured according

• VDI DIN 69880 in sizes 30 and 40 for to h6 tolerance and Ramin = 0.3 ground.

stationary applications on CNC lathes Tools with DIN 6535 HE (whistle notch) shanks

should be used in reduction elements, to

avoid damaging the chucking hole.

• Clean any grease and dirt from the chuck mounting hole

and the tool shank. Insert the tool shank up to the stopper.

Make sure that the minimum chucking length

is maintained.

• Using the hexagonal-headed key, rotate the clamping

screw in a clockwise direction until the end.

Do not attempt to clamp the chuck without a shank inside

as it may break the expansion clamping sleeve.

• To release the tool, turn the clamping screw in

a counterclockwise direction by about 5 or 6

revolutions and remove the tool.

ISCAR

846

846 ISCAR