Page 855 - Iscar

P. 855

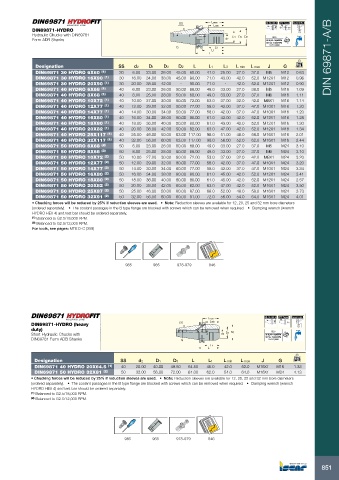

SS Lmax A 0.003 A AT3 Taper 58-60 HRc

Lmin

DIN69871-HYDRO

Hydraulic Chucks with DIN69781 D1 D3 D2 G2.5

Form ADB Shanks d2 SK 30, 40= 18,000RPM

J SK 50= 12,000RPM

U<1.0 gmm

G L3

L1

L DIN 69871-A/B

Designation SS d2 D1 D3 D2 L L1 L3 L min L max J G kg

DIN69871 30 HYDRO 6X60 (1) 30 6.00 23.00 26.00 45.00 60.00 41.0 25.00 27.0 37.0 M5 M12 0.63

DIN69871 30 HYDRO 16X90 (1) 30 16.00 34.00 38.00 45.00 90.00 71.0 43.00 42.0 52.0 M12X1 M12 0.96

DIN69871 30 HYDRO 20X90 (1) 30 20.00 38.00 42.00 - 90.00 71.0 - 42.0 52.0 M12X1 M12 0.90

DIN69871 40 HYDRO 6X68 (1) 40 6.00 23.00 26.00 50.00 68.00 49.0 33.00 27.0 38.0 M5 M16 1.09

DIN69871 40 HYDRO 8X68 (1) 40 8.00 25.00 28.00 50.00 68.00 49.0 33.00 27.0 37.0 M6 M16 1.11

DIN69871 40 HYDRO 10X72 (1) 40 10.00 27.00 30.00 50.00 72.00 53.0 37.00 32.0 42.0 M8X1 M16 1.14

DIN69871 40 HYDRO 12X77 (1) 40 12.00 29.00 32.00 50.00 77.00 58.0 42.00 37.0 47.0 M10X1 M16 1.20

DIN69871 40 HYDRO 14X77 (1) 40 14.00 30.00 34.00 50.00 77.00 58.0 42.00 37.0 47.0 M10X1 M16 1.20

DIN69871 40 HYDRO 16X80 (1) 40 16.00 34.00 38.00 50.00 80.00 61.0 43.00 42.0 52.0 M12X1 M16 1.28

DIN69871 40 HYDRO 18X80 (1) 40 18.00 36.00 40.00 50.00 80.00 61.0 43.00 42.0 52.0 M12X1 M16 1.30

DIN69871 40 HYDRO 20X82 (1) 40 20.00 38.00 42.00 50.00 82.00 63.0 47.00 42.0 52.0 M12X1 M16 1.34

DIN69871 40 HYDRO 25X117 (1) 40 25.00 46.00 50.00 63.00 117.00 98.0 51.00 48.0 58.0 M16X1 M16 2.01

DIN69871 40 HYDRO 32X117 (1) 40 32.00 56.00 60.00 63.00 117.00 98.0 56.00 52.0 62.0 M16X1 M16 2.44

DIN69871 50 HYDRO 6X68 (2) 50 6.00 23.00 26.00 80.00 68.00 49.0 33.00 27.0 37.0 M5 M24 3.10

DIN69871 50 HYDRO 8X68 (2) 50 8.00 25.00 28.00 80.00 68.00 49.0 33.00 27.0 37.0 M6 M24 3.10

DIN69871 50 HYDRO 10X72 (2) 50 10.00 27.00 30.00 80.00 72.00 53.0 37.00 32.0 42.0 M8X1 M24 3.20

DIN69871 50 HYDRO 12X77 (2) 50 12.00 29.00 32.00 80.00 77.00 58.0 42.00 37.0 47.0 M10X1 M24 3.20

DIN69871 50 HYDRO 14X77 (2) 50 14.00 30.00 34.00 80.00 77.00 58.0 42.00 37.0 47.0 M10X1 M24 3.34

DIN69871 50 HYDRO 16X80 (2) 50 16.00 34.00 38.00 80.00 80.00 61.0 45.00 42.0 52.0 M12X1 M24 3.41

DIN69871 50 HYDRO 18X80 (2) 50 18.00 36.00 40.00 80.00 80.00 61.0 45.00 42.0 52.0 M12X1 M24 2.57

DIN69871 50 HYDRO 20X82 (2) 50 20.00 38.00 42.00 80.00 82.00 63.0 47.00 42.0 52.0 M16X1 M24 3.50

DIN69871 50 HYDRO 25X87 (2) 50 25.00 46.00 50.00 80.00 87.00 68.0 52.00 48.0 58.0 M16X1 M24 3.73

DIN69871 50 HYDRO 32X91 (2) 50 32.00 56.00 60.00 80.00 91.00 72.0 56.00 54.0 64.0 M16X1 M24 4.01

• Chucking forces will be reduced by 25% if reduction sleeves are used. • Note: Reduction sleeves are available for 12, 20, 25 and 32 mm bore diameters

(ordered separately). • The coolant passages in the B type flange are blocked with screws which can be removed when required. • Clamping wrench (wrench

HYDRO HEX 4) and test bar should be ordered separately.

(1) Balanced to G2.5/18,000 RPM.

(2) Balanced to G2.5/12,000 RPM.

For tools, see pages: MTE D-C (359)

985 965 978-979 846

Lmax A 0.003 A AT3 Taper 58-60 HRc

DIN69871-HYDRO (heavy SS Lmin

duty) G2.5

Short Hydraulic Chucks with J d2 D1 D3 SK 30, 40= 18,000RPM

DIN69781 Form ADB Shanks G SK 50= 12,000RPM

U<1.0 gmm

L1

L

Designation SS d2 D1 D3 L L1 L min L max J G kg

DIN69871 40 HYDRO 20X64.5 (1) 40 20.00 40.00 49.50 64.50 45.0 42.0 52.0 M16X1 M16 1.33

DIN69871 50 HYDRO 32X81 (2) 50 32.00 56.00 72.00 81.00 62.0 54.0 64.0 M16X1 M24 4.13

• Chucking forces will be reduced by 25% if reduction sleeves are used. • Note: Reduction sleeves are available for 12, 20, 25 and 32 mm bore diameters

(ordered separately). • The coolant passages in the B type flange are blocked with screws which can be removed when required. • Clamping wrench (wrench

HYDRO HEX 4) and test bar should be ordered separately.

(1) Balanced to G2.5/18,000 RPM.

(2) Balanced to G2.5/12,000 RPM.

985 965 978-979 846

851