Page 670 - Iscar

P. 670

USER GUIDE

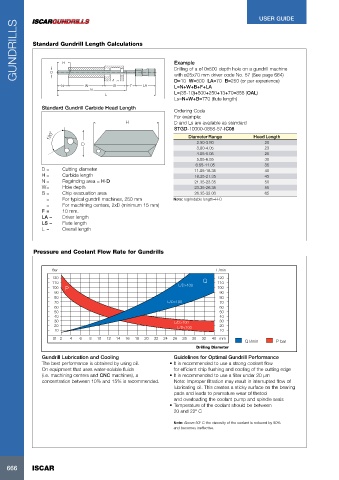

GUNDRILLS Standard Gundrill Length Calculations Example

H

Drilling of a ø10x500 depth hole on a gundrill machine

D

D=10 W=500 LA=70 B=250 (or per experience)

N W B F LA with ø25x70 mm driver code No. 57 (See page 664)

L=N+W+B+F+LA

Ls

L L=(35-10)+500+250+13+70=858 (OAL)

Ls=N+W+B=770 (flute length)

Standard Gundrill Carbide Head Length

Ordering Code

For example:

H D and Ls are available as standard

STGD-10000-0858-57-IC08

Diameter Range Head Length

D 2.50-3.80 20

3.80-4.05 23

4.05-5.05 25

5.05-6.55 30

6.55-11.05 35

D = Cutting diameter 11.05-18.35 40

H = Carbide length 18.35-21.35 45

N = Regrinding area = H-D 21.35-23.35 50

W = Hole depth 23.35-26.35 55

B = Chip evacuation area 26.35-32.00 65

= For typical gundrill machines, 250 mm Note: regrindable length=H-D

= For machining centers, 2xD (minimum 15 mm)

F = 10 mm.

LA = Driver length

LS = Flute length

L = Overall length

Pressure and Coolant Flow Rate for Gundrills

Bar L/min

120 120

110 L/D>100 Q 110

100 P 100

90 90

80 80

70 L/D<100 70

60 60

50 50

40 40

30 L/D>100 30

20 L/D<100 20

10 10

Ø 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 40 mm

Q l/min P bar

Drilling Diameter

Gundrill Lubrication and Cooling Guidelines for Optimal Gundrill Performance

The best performance is obtained by using oil. • It is recommended to use a strong coolant flow

On equipment that uses water-soluble fluids for efficient chip flushing and cooling of the cutting edge

(i.e. machining centers and CNC machines), a • It is recommended to use a filter under 20 µm

concentration between 10% and 15% is recommended. Note: Improper filtration may result in interrupted flow of

lubricating oil. This creates a sticky surface on the bearing

pads and leads to premature wear of thetool

and overloading the coolant pump and spindle seals

• Temperature of the coolant should be between

20 and 22º C

Note: Above 50º C the viscosity of the coolant is reduced by 50%

and becomes ineffective.

666 ISCAR