Page 665 - Iscar

P. 665

USER GUIDE

GUNDRILLS

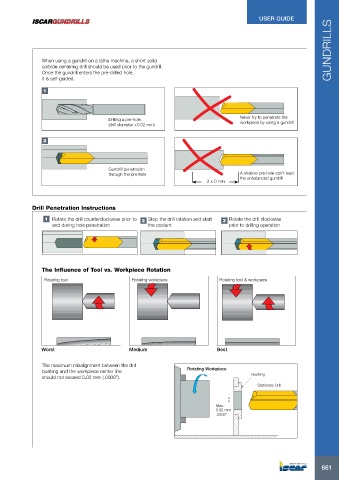

When using a gundrill on a lathe machine, a short solid

carbide centering drill should be used prior to the gundrill.

Once the gundrill enters the pre-drilled hole,

it is self-guided.

1

Never try to penetrate the

Drilling a pre-hole

(drill diameter +0.02 mm) workpiece by using a gundrill

2

Gundrill penetration

through the pre-hole A shallow pre-hole can’t lead

the unbalanced gundrill

2 x D min

Drill Penetration Instructions

1 Rotate the drill counterclockwise prior to 2 Stop the drill rotation and start 3 Rotate the drill clockwise

and during hole penetration the coolant prior to drilling operation

The Influence of Tool vs. Workpiece Rotation

Rotating tool Rotating workpiece Rotating tool & workpiece

Worst Medium Best

The maximum misalignment between the drill

bushing and the workpiece center line Rotating Workpiece

should not exceed 0.02 mm (.0008”). Bushing

Stationary Drill

Max.

0.02 mm

.0008"

661