Page 458 - Iscar

P. 458

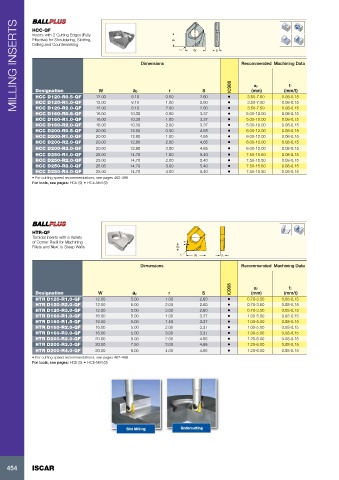

MILLING INSERTS HCC-QF Dimensions ap r W S IC908 Recommended Machining Data

Inserts with 2 Cutting Edges (Fully

Effective) for Shouldering, Slotting,

Drilling and Countersinking

ap

fz

S

(mm/t)

Designation

W

(mm)

r

ap

HCC D120-R0.5-QF

8.10

3.50-7.50

•

1.00

2.60

12.00

0.08-0.15

8.10

HCC D120-R1.0-QF

3.50-7.50

•

8.10

12.00

0.08-0.15

2.60

2.00

HCC D120-R2.0-QF

3.50-7.50

•

HCC D160-R0.5-QF 12.00 10.30 0.50 2.60 • 5.00-10.00 0.08-0.15

3.37

0.50

16.00

0.08-0.15

HCC D160-R1.0-QF 16.00 10.30 1.00 3.37 • 5.00-10.00 0.08-0.15

HCC D160-R2.0-QF 16.00 10.30 2.00 3.37 • 5.00-10.00 0.08-0.15

HCC D200-R0.5-QF 20.00 12.80 0.50 4.65 • 6.00-12.00 0.08-0.15

HCC D200-R1.0-QF 20.00 12.80 1.00 4.65 • 6.00-12.00 0.08-0.15

HCC D200-R2.0-QF 20.00 12.80 2.00 4.65 • 6.00-12.00 0.08-0.15

HCC D200-R3.0-QF 20.00 12.80 3.00 4.65 • 6.00-12.00 0.08-0.15

HCC D250-R1.0-QF 25.00 14.70 1.00 5.40 • 7.50-15.50 0.08-0.15

HCC D250-R2.0-QF 25.00 14.70 2.00 5.40 • 7.50-15.50 0.08-0.15

HCC D250-R3.0-QF 25.00 14.70 3.00 5.40 • 7.50-15.50 0.08-0.15

HCC D250-R4.0-QF 25.00 14.70 4.00 5.40 • 7.50-15.50 0.08-0.15

• For cutting speed recommendations, see pages 462-498

For tools, see pages: HCE (9) • HCE-MM (9)

HTR-QF

Toroidal Inserts with a Variety

of Corner Radii for Machining 7°

Fillets and Next to Steep Walls ap

r W S

Dimensions Recommended Machining Data

IC908 ap fz

Designation W ap r S (mm) (mm/t)

HTR D120-R1.0-QF 12.00 5.00 1.00 2.60 • 0.70-3.50 0.08-0.15

HTR D120-R2.0-QF 12.00 5.00 2.00 2.60 • 0.70-3.50 0.08-0.15

HTR D120-R3.0-QF 12.00 5.00 3.00 2.60 • 0.70-3.50 0.08-0.15

HTR D160-R1.0-QF 16.00 5.00 1.00 3.37 • 1.00-5.00 0.08-0.15

HTR D160-R1.5-QF 16.00 5.00 1.50 3.37 • 1.00-5.00 0.08-0.15

HTR D160-R2.0-QF 16.00 5.00 2.00 3.37 • 1.00-5.00 0.08-0.15

HTR D160-R3.0-QF 16.00 5.00 3.00 3.37 • 1.00-5.00 0.08-0.15

HTR D200-R2.0-QF 20.00 8.00 2.00 4.65 • 1.20-6.00 0.08-0.15

HTR D200-R3.0-QF 20.00 7.50 3.00 4.65 • 1.20-6.00 0.08-0.15

HTR D200-R4.0-QF 20.00 8.00 4.00 4.65 • 1.20-6.00 0.08-0.15

• For cutting speed recommendations, see pages 462-498

For tools, see pages: HCE (9) • HCE-MM (9)

454 ISCAR