Page 456 - Iscar

P. 456

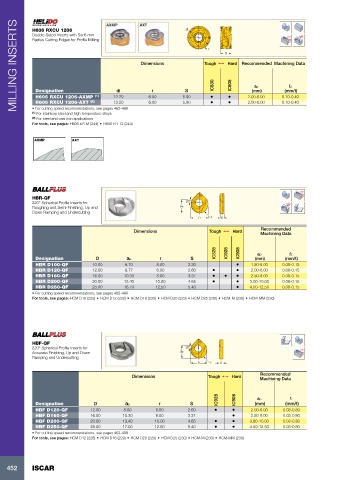

MILLING INSERTS H606 RXCU 1206 Dimensions di Tough 1 Hard Recommended Machining Data

Double-Sided Inserts with Six 6 mm

Rd°

Radius Cutting Edges for Profile Milling

r

S

IC808

IC830

ap

fz

Designation

S

r

di

(mm)

(mm/t)

H606 RXCU 1206-AXMP

(1)

•

•

(2)

H606 RXCU 1206-AXT

5.90

6.00

12.20

0.10-0.40

2.00-6.00

• For cutting speed recommendations, see pages 462-498

(1) For stainless steel and high temperature alloys 12.20 6.00 5.90 • • 2.00-6.00 0.10-0.40

(2) For steel and cast iron applications

For tools, see pages: H606 ER-M (244) • H606 FR-12 (244)

AXMP AXT

Rd°

HBR-QF

220° Spherical Profile Inserts for 20°

Roughing and Semi-Finishing, Up and ap

Down Ramping and Undercutting

r

D S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC928 IC908 ap fz

Designation D ap r S (mm) (mm/t)

HBR D100-QF 10.00 6.70 5.00 2.30 • 1.50-5.00 0.08-0.15

HBR D120-QF 12.00 9.77 6.00 2.60 • • 2.00-6.00 0.08-0.15

HBR D160-QF 16.00 10.30 8.00 3.37 • • • 2.50-8.00 0.08-0.15

HBR D200-QF 20.00 13.40 10.00 4.65 • • 3.00-10.00 0.08-0.15

HBR D250-QF 25.00 16.70 12.50 5.40 • 4.00-12.50 0.08-0.15

• For cutting speed recommendations, see pages 462-498

For tools, see pages: HCM D10 (228) • HCM D12 (228) • HCM D16 (229) • HCM D20 (229) • HCM D25 (230) • HCM-M (230) • HCM-MM (230)

HBF-QF

220° Spherical Profile Inserts for 20° Rd°

Accurate Finishing, Up and Down ap

Ramping and Undercutting

D r S

Recommended

Dimensions Tough 1 Hard Machining Data

IC928 IC908 ap fz

Designation D ap r S (mm) (mm/t)

HBF D120-QF 12.00 8.00 6.00 2.60 • • 2.00-6.00 0.03-0.80

HBF D160-QF 16.00 10.30 8.00 3.37 • 2.50-8.00 0.03-0.80

HBF D200-QF 20.00 13.40 10.00 4.65 • • 3.00-10.00 0.03-0.80

HBF D250-QF 25.00 17.00 12.50 5.40 • • 4.00-12.50 0.03-0.80

• For cutting speed recommendations, see pages 462-498

For tools, see pages: HCM D12 (228) • HCM D16 (229) • HCM D20 (229) • HCM D25 (230) • HCM-M (230) • HCM-MM (230)

452 ISCAR