Page 329 - Iscar

P. 329

USER GUIDE

Stacked Cutters (1)

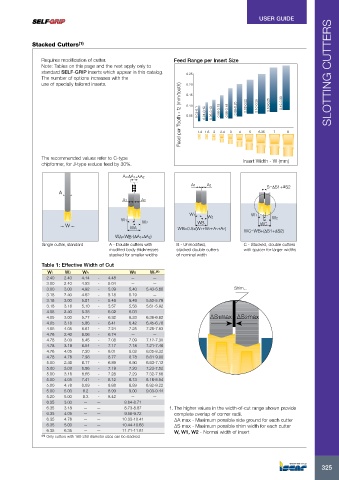

Requires modification of cutter. Feed Range per Insert Size

Note: Tables on this page and the next apply only to

standard SELF-GRIP inserts which appear in this catalog. 0.25 SLOTTING CUTTERS

The number of options increases with the

use of specially tailored inserts. 0.20

Feed per Tooth - fz (mm/tooth) 0.10 0.04-0.1 1.4 0.04-0.12 1.6 0.05-0.13 2 0.06-0.15 2.4 0.06-0.18 3 0.08-0.20 4 0.08-0.22 5 0.10-0.25 6.35 0.10-0.25 7 0.12-0.30 8

0.15

0.05

The recommended values refer to C-type Insert Width - W (mm)

chipformer, for J-type reduce feed by 30%.

A=ΔA 1+ΔA2

A1 A2 S=ΔS1+ΔS2

A

A1 A2

W1 W2 W1

W1 W2 W2

W WA WB WC

WB=0.5x(W1+W2+A1+A2)

WC=WB+(ΔS1+ΔS2)

WA=WB-(ΔA 1 +ΔA 2)

Single cutter, standard A - Double cutters with B - Unmodified, C - Stacked, double cutters

modified body thicknesses stacked double cutters with spacer for larger widths

stacked for smaller widths of nominal width

Table 1: Effective Width of Cut

W1 W2 WA WB Wc (1)

2.40 2.40 4.14 - 4.48 — —

3.00 2.40 4.53 - 5.04 — —

3.00 3.00 4.92 - 5.39 5.40 5.43-5.60 Shim...

3.18 2.40 4.62 - 5.18 5.19 —

3.18 3.00 5.01 - 5.48 5.49 5.52-5.76

3.18 3.18 5.10 - 5.57 5.58 5.61-5.92

4.05 2.40 5.38 - 6.02 6.03 —

4.05 3.00 5.77 - 6.32 6.33 6.36-6.62 ∆S1max ∆S 2max

4.05 3.18 5.86 - 6.41 6.42 6.45-6.78

4.05 4.05 6.61 - 7.24 7.25 7.28-7.63

4.78 2.40 6.06 - 6.74 — —

4.78 3.00 6.45 - 7.08 7.09 7.12-7.30

4.78 3.18 6.54 - 7.17 7.18 7.21-7.46

4.78 4.05 7.30 - 8.01 8.02 8.05-8.32

4.78 4.78 7.98 - 8.77 8.78 8.81-9.00

5.00 2.40 6.17 - 6.89 6.90 6.93-7.12

5.00 3.00 6.56 - 7.19 7.20 7.23-7.52

5.00 3.18 6.65 - 7.28 7.29 7.32-7.68

5.00 4.05 7.41 - 8.12 8.13 8.16-8.54

5.00 4.78 8.09 - 8.88 8.89 8.92-9.22

5.00 5.00 8.2 - 8.99 9.00 9.03-9.44

5.20 5.00 8.3 - 8.42 — —

6.35 3.00 — — 8.64-8.71

6.35 3.18 — — 8.73-8.87 1. The higher values in the width-of-cut range shown provide

6.35 4.05 — — 9.56-9.72 complete overlap of corner radii.

6.35 4.78 — — 10.33-10.41 ∆A max - Maximum possible side ground for each cutter

6.35 5.00 — — 10.44-10.63 ∆S max - Maximum possible shim width for each cutter

6.35 6.35 — — 11.71-11.81 W, W1, W2 - Normal width of insert

(1) Only cutters with 160-250 diameter sizes can be stacked.

325

325